HF Q Guard: Precision, quality, traceability

- By 0

- May 06, 2020

HF Tire Tech Group is one the largest manufacturers of high-end technical, tyre building machines and curing presses in the global tyre industry.

“HF Q Guard is the next step to our HF ONE tyre building machine and lifts tyre production to a new level when it comes to precision, quality and traceability. High-resolution images are taken with LEDs. We can get details of the height and width of materials inside the high-resolution images. HF Q Guard can also detect the edge of the materials, and that is a new thing,” said Hartmut Hoops, Head of Process Engineering, Tire Building Machines, HF TireTech Group.

.jpg)

HF Q Guard comes into two variants: HF Q Guard 1000 and HF Q400 covering inspection width of 1000mm and 400 mm respectively. HF Q Guard sensor technology works with high precision and accuracy. It measures splices in real-time with an accuracy lower than half of a millimetre. The system covers a drum speed of up to 1500 mm/s speed, and distance to the surface is about 1.4 metres.

With its features, the HF Q Guard offers advantages to over the current laser splice measurement systems, which have to be closer to the drums, need better light and are sensitive to vibrations of the drums.

Another feature of HF Q Guard is its compatibility to the existing and new tyre building machines available in the market, and it can be integrated very quickly and at low cost.

The new product is so robust, which could be fitted at any position to the drums, which is another advantage over the laser splice measuring machines. As it takes a few hours for installation, HF Q Guard needs minimal production downtime.

“The whole system is calibrated. A key factor about the installation of HF Q Guard is that we need a few information. We need to know the positioning of the drums. We can start with very limited interfacing to the machines. We need some information as such as the layer sequence, building procedure and tolerance of the tyres. Data collection is initiated by elegant technology,” says Hoops.

Over the years, HF has developed innovative products that can be upgraded easily. The company has developed machine platforms such as PCR/LTR, PLT 2, and PLT 2 SD along with the award-winning HF ONE for which upgrades are planned to include the latest technologies such as auto bead loading, automated tyre handling, and the latest control systems with state-of-the-art HMIs. Servers can be added for additional strips such as Run-Flat technology or reinforcement strips.

According to the company, HF Q Guard can be used with almost all platforms.

Tyres could be damaged due to defective manufacturing. During manufacturing, if cord-cutting, building or vulcanising process are not done correctly, it could lead to damages in the tyres. The result is that the inner layers of the tyre are too close to the surface or that structural defects in the tyre occur. HF Q Guard significantly reduces the risk of the faulty tyre through permanent quality checks. The digital twin of a tyre can thus store the complete data on the surface of each layer and all splice length information.

“We have one IPC which does the algorithm for splice analysing, and that also connects to the cameras, and compression of data. We could also have possibilities to connect the existing PLCs in the machines, and we can connect data such as tolerance, width, building sequence as from there as well. On other hands, there are new tyre building machines have their data set on built tyres, and we can combine all data from the splice measurement systems and the machines itself for analysing systems,” said Hoops.

Measurement data of tyres are prepared for visualisation according to individual needs, and this makes it possible to inspect the individual surfaces of the materials to identify defects in the construction or the tyre material used. Expand the existing scope of functions of the splice measurement of the HF Q Guard at any time to include features needed for improving quality assurance. HF Q Guard grows with specific requirements.

Overall market trends for the mobility and regulatory pressure are putting pressure on tyre manufacturing to have equipment that not only makes quality products but also are smart, flexible and compatible. OEs will be more focused to check its supplier’s consistency in process and quality. From tyre makers, OEs now expect data on the material mix, extrusion process, tyre building, curing and finished products.

As HF Q Guard collects data and manages the complete documentation, it can help to prove that non-defect building of tyres at the factory any point of time.

The company has already spent a year on engineering the units and hardware, cameras and other components running.

In the next six months, HF Tire Tech will work on the collection of data and the results of HF Q Guard, and after that, the company will bring the product into the market.

“HF Q Guard has been tested in house on materials and are still in the process do the same in next months. We start a field test in the next months. The company will install HF Q Guard at the customer’s factory to collect the data, and the company already found the customer to conduct the actual test,” said Hoops. HF Group, the global market leader in machinery and systems for the rubber processing tyre industry, has brought out another innovation, HF Q Guard, to meet the growing demand for precision in splice measuring, quality control and traceability in the entire manufacturing process.

- Global Data Service Organisation for Tyres and Automotive Components

- GDSO

- RAIN Alliance

- RAIN RFID

- Digital Tyre Identification Standards

GDSO And RAIN Alliance Join Hands To Advance Digital Tyre Identification Standards

- By TT News

- February 13, 2026

The Global Data Service Organisation for Tyres and Automotive Components (GDSO) has entered into a Memorandum of Understanding with the RAIN Alliance, a move designed to accelerate the harmonisation of electronic tyre identification and support broader digitalisation throughout the international tyre value chain. This agreement formalises a mutual commitment to advancing interoperable, scalable and globally consistent standards that can be adopted across the sector.

GDSO is responsible for establishing and promoting global data standards for tyres, enabling comprehensive lifecycle applications that serve a diverse group of stakeholders – from manufacturers and logistics providers to fleet managers, recyclers and regulatory bodies. The RAIN Alliance, in parallel, champions the widespread implementation of RAIN RFID technology within a framework that is open, standards-based and interoperable.

The growing importance of electronic tyre identification is underscored by its role in enabling traceability, meeting regulatory requirements, advancing circular economy goals and improving operational performance. Within existing standardisation frameworks, embedded RAIN RFID technology is currently the sole passive data carrier capable of supporting item-level traceability across the full lifespan of a tyre. This partnership seeks to align data standardisation efforts with the underlying identification technologies, thereby reinforcing the ecosystem necessary for reliable and scalable digital identification solutions worldwide.

Although GDSO acknowledges the established position and technical maturity of RAIN RFID, the organisation maintains a technology-agnostic stance. Its primary focus remains on developing robust and adaptable global data standards that foster an inclusive and resilient identification ecosystem. Such an approach supports ongoing innovation and ensures that all actors across the tyre value chain can participate effectively, regardless of future technological shifts.

Through this alliance, GDSO and the RAIN Alliance intend to drive globally aligned standards, enhance system interoperability, support digital use cases throughout the product lifecycle and contribute meaningfully to sustainability and circularity targets. This partnership reflects a shared strategic vision to strengthen the digital infrastructure underpinning the tyre industry.

Riccardo Giovannotti, Secretary General, GDSO, said, “I’m pleased to share that GDSO has signed a collaboration MoU with RAIN Alliance. The collaboration is grounded in a shared commitment to industry-wide standards and to advancing digitalisation across the tyre value chain. As the organisation leading the definition and deployment of global data standards for tyres, GDSO focuses on enabling cradle-to-grave use cases through interoperable and scalable solutions. Within today’s standardisation landscape, the embedded RAIN RFID (i.e. passive RFID) is currently the only data carrier standardised and technically capable of supporting item-level identification across the full tyre lifecycle, which makes this collaboration both relevant and timely.”

- Titan International

- Cerebrum Sensor Technologies

- Pressure Perfect

- P2

- Intelligent Tyre Solutions

- Agricultural Tyre Intelligence

Titan And Cerebrum Unveil Pressure Perfect, A Breakthrough In Agricultural Tyre Intelligence

- By TT News

- February 11, 2026

A new milestone in agricultural tyre technology has been achieved through the partnership of Titan International, Inc. and Cerebrum Sensor Technologies, Inc. Together, they have unveiled Titan Pressure Perfect (P2), a smart sensor system designed to transform how farm tyres perform and communicate. This system marks the emergence of a broader category known as Intelligent Tyre Solutions (iTS), developed jointly by the two companies.

At the core of Pressure Perfect (P2) is real-time monitoring of tyre pressure, temperature and load. This data enables continuous oversight and works seamlessly with onboard inflation systems, allowing automatic pressure adjustments while the vehicle is in motion. Whether shifting from roadway to field or responding to varying load demands, the system can reduce air pressure by as much as half. This flexibility helps lower soil compaction by up to 35 percent and has been linked to potential corn yield increases of four to six percent.

Pressure Perfect is compatible with all Titan and Goodyear Farm Tyre products and integrates with nearly all inflation management systems already in use. By supporting more precise tyre management, it contributes to longer tyre life, improved machine efficiency and reduced environmental impact through less ground disturbance.

The innovation draws on Cerebrum’s licensed portfolio of patented technologies, including advanced sensors, proprietary algorithms and sophisticated software capabilities. This technical foundation sets a new standard for intelligent tyre management in agriculture. While other industry players focus on replicating existing central tyre inflation and tyre pressure monitoring systems, Titan and Cerebrum are advancing a more comprehensive and forward-looking approach. Pressure Perfect reflects Titan’s longstanding engineering heritage and its continued commitment to leading the field through purposeful collaboration and applied innovation.

Dubbing it the ‘Holy Grail’ of innovations, Scott Sloan, Global Ag & LSW Product Manager for Titan, said, “This is the first system of its kind that delivers dynamic inflation management. Load, tyre pressure and temperature data are gathered by a single tyre-mounted sensor and integrated with tyre-industry load-inflation tables in real time. Imagine bringing together Central Tyre Inflation System (CTIS) and Tyre Pressure Monitoring System (TPMS) technologies, and now they can work together and talk to each other – all without operator intervention."

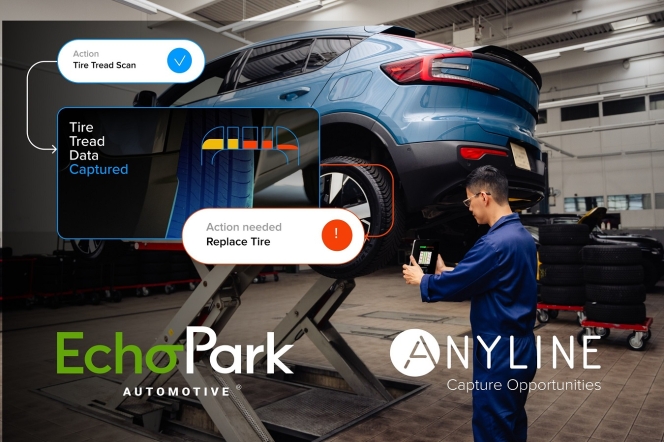

Anyline Displays TireBuddy Platform At NADA 2026

- By TT News

- February 04, 2026

Anyline is displaying its AI-powered TireBuddy platform at the 2026 National Automobile Dealers Association (NADA) Show in Las Vegas (from 3–6 February), demonstrating how it brings objective, digital tyre inspections to automotive retailers. The technology, which standardises tread depth and condition assessments, is used by dealerships, reconditioning centres and independent shops to enhance operational consistency and customer transparency. At Booth 7649N, live demonstrations will show the system’s guided scanning and intuitive workflow, which technicians have adopted for its ability to generate clear, data-backed reports directly in the service bay.

A key adopter includes EchoPark, a national pre-owned vehicle retailer under Sonic Automotive, Inc., which utilises TireBuddy as part of its rigorous 190-point vehicle inspection process across multiple states. The platform provides repeatable measurements that strengthen technical recommendations and build buyer confidence by turning subjective checks into documented insights. Since its 2025 launch, the tool has been implemented by large-scale automotive groups seeking to improve decision-making and efficiency.

Anyline’s exhibition will focus on these real-world applications, showing how digitising tyre inspections creates a more transparent and trustworthy service experience. By replacing visual estimates with precise digital data, TireBuddy helps businesses streamline workflows, empower technicians and ultimately support safer, more reliable vehicle assessments for customers.

Christoph Braunsberger, CEO, Anyline, said, “Our goal with TireBuddy is to equip technicians with the tools they need to make accurate, fast and confident decisions, an important message we’re bringing to the forefront at this year’s NADA Show. By providing objective, AI-powered data, TireBuddy delivers a far clearer path to cost savings, operational efficiency and customer transparency for retailers – benefits that matter at every level of their operation.”

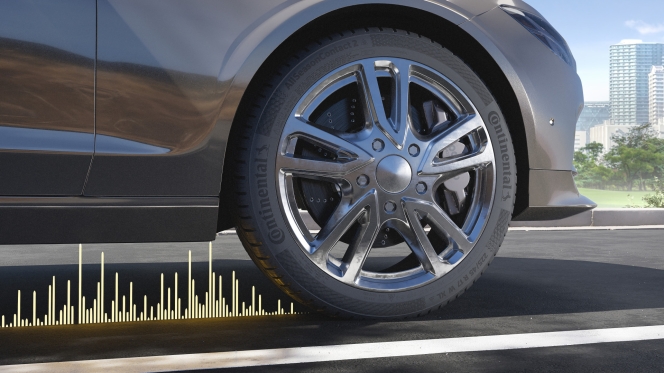

Continental Innovates Tyre Technologies For Quieter Driving

- By TT News

- January 30, 2026

As urban areas around the world grow increasingly louder, traffic noise has emerged as a critical environmental and public health challenge. Recognised by health authorities as a major risk factor, this pervasive issue extends from European cities to megacities across Asia and Latin America. Continental is addressing this problem by pioneering tyre technologies that significantly reduce rolling noise, thereby contributing to quieter urban environments and enhanced in-vehicle comfort.

The transition to electric mobility has brought tyre noise into sharper focus. With the near-silent operation of electric motors replacing traditional engine sounds, the acoustic contribution from tyres becomes far more prominent, even at moderate city driving speeds. In response, Continental engineers have developed specialised solutions that target noise generation without compromising the safety, durability or performance of the tyre.

One such innovation is the Silent Pattern tread design, featured on models like the EcoContact 7. This technology disrupts the conventional, uniform arrangement of tread blocks that typically creates a rhythmic humming sound on pavement. By intelligently varying the spacing and angles of these blocks, the pattern breaks up this acoustic consistency. Furthermore, it is tuned to cancel out specific sound frequencies, akin to the principle behind noise-cancelling headphones. This results in a measurable reduction of traffic noise at speeds around 50 kmph, where rolling noise is most perceptible to pedestrians and residents.

For reducing noise inside the vehicle cabin, Continental employs its ContiSilent technology. This involves lining the inside of the tyre with a lightweight polyurethane foam that absorbs vibrations caused by the tyre’s contact with the road. By dampening these air vibrations, the technology can cut perceived in-cabin rolling noise by up to nine decibels – a reduction the human ear experiences as nearly halving the volume. This substantial increase in acoustic comfort is integrated into various product lines, including high-performance summer tyres, without affecting driving dynamics or efficiency.

The company’s commitment to low-noise mobility spans multiple vehicle segments. From the Conti Urban NXT for city buses to passenger car tyres like the EcoContact 6 Q and van tyres such as the VanContact A/S Eco, these products are designed to meet stringent noise standards. Consumers can readily identify these quieter options through regulatory labels, like the EU tyre label, which provides clear decibel ratings for external rolling noise. Through these continuous advancements in tread design and sound-dampening materials, Continental is systematically working to diminish the acoustic footprint of road traffic.

According to Achillefs Tsotras, head of Continental’s Tyre-Vehicle Interaction department, “Noise, especially traffic noise from cars, buses and delivery vehicles, is a major burden for people and the environment. With tyre technologies like ContiSilent and innovative tread designs, we are actively reducing rolling noise without compromising safety. This makes every ride noticeably quieter, benefiting drivers, pedestrians, residents and the environment alike.”

Comments (0)

ADD COMMENT