From Tyre Waste To Sustainable Infrastructure: IIT Bombay’s Vision For A Greener Future

- By Nilesh Wadhwa

- December 17, 2025

As the world grapples with the environmental challenges of discarded tyres, IIT Bombay researchers are developing sustainable solutions by repurposing waste rubber into innovative construction materials. Nilesh Wadhwa reports on how their work not only aims to mitigate landfill waste but also offers unique thermal, electrical and structural benefits for future infrastructure.

With over a billion tyres discarded globally each year, the world faces an escalating crisis in managing tyre waste. Beyond the mounds of rubber in landfills, the environmental and health hazards from tyre degradation, microplastics and toxic emissions are profound. However, a team of researchers at the Indian Institute of Technology (IIT) Bombay is charting a sustainable path forward. By transforming waste tyres into innovative construction materials – Rubcrete, which is a form of concrete mixed with shredded waste tyres. This is said to not only provide strength to the material but also make it more environmentally friendly. The idea is to turn an environmental problem into a valuable resource for civil engineering.

In an interaction with Tyre Trends, Prithvendra Singh, a principal researcher at IIT Bombay, explained the motivations behind this ground-breaking research. “The main aim of this research was to address the dual challenge of excessive end-of-life tyre (ELT) accumulation and the unsustainable depletion of natural aggregates due to ever-rising demand in infrastructural development,” he stated.

By converting waste rubber into engineered rubber aggregates (RA) and rubber-plastic blends (RPB), the team seeks to not only reduce landfill dependency but also enhance the sustainability of construction materials.

This pioneering approach is timely. The sheer scale of tyre waste, with millions of tonnes generated annually, has far-reaching consequences. Tyres are durable, non-biodegradable and pose serious fire hazards.

“One of the most overlooked issues is the generation of microplastics and toxic volatile compounds through tyre wear and tear, degradation, weathering or fires. Landfilled rubber fires can take months to extinguish and result in the emission of carcinogenic gases. These pose risks to human health and ecosystems, and their long-term contamination potential – especially via water, soil and air – is often overlooked in conventional waste management frameworks,” emphasised Singh.

FROM LAB TO FIELD

The IIT Bombay team’s research has revealed promising properties in both RA and RPB, which could revolutionise the use of secondary materials in civil engineering.

Singh elaborated on the mechanical characteristics, “RA and RPB exhibit significantly lower stiffness and higher deformability than natural aggregates, which makes them suitable for specific geoenvironmental applications but limits their use under high structural loads.”

While these properties may exclude them from load-bearing infrastructure, they open up opportunities in other areas. “Despite their lower mechanical strength, both materials demonstrate promising insulation characteristics and environmental safety under controlled conditions,” Singh added.

While these properties may exclude them from load-bearing infrastructure, they open up opportunities in other areas. “Despite their lower mechanical strength, both materials demonstrate promising insulation characteristics and environmental safety under controlled conditions,” Singh added.

Thermal and electrical insulation capabilities are where these materials truly shine. “Both RA and RPB have superior thermal resistivity compared to standard sand, confirming their suitability for thermal insulation. Electrically, dry RPB shows the lowest conductivity, making it highly suitable for electrical insulation applications. Both materials also act as excellent dielectric materials over a broad frequency range,” Singh explained.

These characteristics make them ideal for construction projects where insulation and resistance to extreme temperatures or electrical fields are critical, such as in utility corridors or specialised building applications.

However, the journey from laboratory research to real-world applications is not without its challenges. “The lower stiffness of RA leads to higher vertical deformation under applied loads, making them less suitable for high-load applications such as base layers of highways,” Singh pointed out.

“However, they are ideal for lightweight fill applications like embankments or drainage layers, where flexibility and energy absorption are more beneficial than stiffness,” he added.

This insight highlights the potential for using RA and RPB in applications where traditional materials fall short, such as in earthquake-prone regions or on unstable soils where flexibility can mitigate damage. The process of creating RA and RPB depends heavily on the methods used to shred and process waste tyres.

SHREDDING METHODS: BALANCING COSTS AND PERFORMANCE

Singh outlined the pros and cons of various shredding technologies. “Ambient shredding is cost-effective but produces rough-surfaced particles, which exhibit better interaction in cement and polymer composites,” he noted. “Cryogenic shredding yields smoother particles with a broader size distribution but poorer bonding characteristics, and the created particles are generally suitable for turf or sports surfaces. Water-jet grinding offers finer control over particle size but comes at high energy and equipment costs.”

Each method results in materials with distinct properties, influencing their performance in construction applications.

Real-world validation is a crucial step in advancing this technology. To this end, IIT Bombay has partnered with GRP India, a leader in rubber recycling.

“We are currently collaborating with GRP to venture into production and field applications of these sustainable aggregates,” Singh revealed. “This partnership provides a foundation for scaling up through industrial-grade shredding, blending and real-world performance validation.”

These collaborations not only bring academic research closer to commercial implementation but also offer a model for future partnerships between academia and industry.

Of course, environmental safety remains a central concern in adopting new construction materials, especially those derived from waste. Leaching of metals and organic contaminants can pose long-term risks if not properly managed.

Singh’s team addressed these concerns through rigorous testing. “ICP-AES analysis showed that heavy metals like Pb and Zn are present in low concentrations, well within permissible limits,” he reported. “Previous studies corroborate that such materials typically stay within permissible toxicity limits under standard conditions. However, long-term leaching behaviour under varied field conditions remains necessary to confirm safety under varying environmental exposures.” This underscores the need for comprehensive testing and monitoring to ensure environmental safety.

THE ROAD AHEAD

Looking forward, IIT Bombay’s research agenda is ambitious. Singh described plans for further experimentation to expand the applications of RA and RPB. “We are currently planning long-term loading-unloading experiments and elevated temperature testing to establish the thermo-mechanical response of RA and RPB under realistic field stresses,” he said. “These experiments aim to address limitations in durability data and expand application potential. Also, future experiments will simulate realistic landfill environments, including interactions with leachate, microbes, humidity and temperature, to understand long-term behaviour.” Such studies will be essential for certifying these materials for broader use in civil engineering.

Could tyre-derived materials eventually replace traditional aggregates in certain applications? Singh is optimistic. “Yes, particularly in non-structural or semi-structural applications such as leachate drainage layers, landfill covers, thermal insulation barriers and lightweight embankments. The lightweight, high porosity and insulation capabilities of the RA and RPB present unique advantages that traditional aggregates cannot provide,” he said.

This vision aligns with global efforts to promote circular economies and reduce reliance on finite natural resources.

Responding to his expectations from the industry, Singh stated that stakeholders need to support the integration of sustainable materials into mainstream construction.

“The message I would like to convey to the academicians, tyre industry stakeholders and policymakers is to embrace innovation through cross-sectoral collaboration. Sustainable solutions like RA and RPB not only offer environmental remediation but also open new markets for green construction materials. With the right policy incentives, certification frameworks and industry support, we can mainstream these materials and accelerate the transition towards a circular, resilient economy,” he said.

IIT Bombay’s work exemplifies how innovative research, when coupled with industry collaboration and policy support, can turn a pressing environmental problem into a sustainable solution. By reimagining waste as a resource, Singh and his team aim to not only address the tyre waste crisis but also lay the groundwork for more resilient and eco-friendly infrastructure in the future.

Bekaert Acquires Steel Cord Business From Bridgestone In China And Thailand

- By TT News

- January 28, 2026

In a strategic expansion of its global footprint, Bekaert has agreed to acquire Bridgestone’s tyre reinforcement operations in China and Thailand, encompassing the tyre cord production facilities in China (Bridgestone (Shenyang) Steel Cord Co., Ltd) and Thailand (Bridgestone Metalpha (Thailand) Co. Ltd.). This move significantly strengthens the market leadership of Bekaert’s Rubber Reinforcement division, its largest business unit, which has led the global tyre cord sector for decades. The acquisition, set for completion in the first half of 2026 pending regulatory approvals, is a continuation of the division's proven strategy in integrating the captive production of major global accounts.

This transaction reinforces the enduring strategic partnership between Bekaert and Bridgestone, a leading tyre manufacturer. As part of Bridgestone's mid-to-long term plan to boost competitiveness through collaboration, the deal includes a long-term supply agreement ensuring continued provision of high-quality tyre reinforcement. For Bekaert, the integration of these two established production facilities enhances its manufacturing presence and solidifies its position in the tyre cord market.

Financially, the acquisition is projected to contribute approximately EUR 80 million in annual consolidated sales for Bekaert. The purchase involves a cash consideration of EUR 60 million, which will be drawn from the company's existing cash reserves. By securing these key assets and a lasting supply partnership, Bekaert not only expands its operational scale but also deepens its trusted supplier relationship with a pivotal global account.

Yves Kerstens, CEO, Bekaert, said, “Bekaert and Bridgestone share a longstanding strategic partnership built on mutual trust and collaboration. When the transaction closes, we are delighted to welcome the plant teams to Bekaert and remain committed to joint growth and innovation with Bridgestone. The acquisition is also a clear signal of strengthening our global leadership position in the tyre reinforcement industry.”

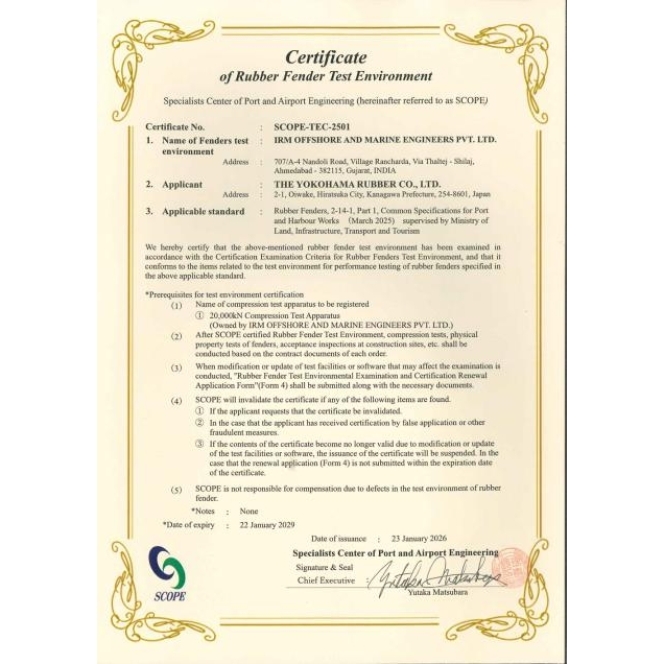

Yokohama Rubber Secures Certificate Of Rubber Fender Test Environment

- By TT News

- January 28, 2026

The Yokohama Rubber Co., Ltd. has successfully secured a Certificate of Rubber Fender Test Environment from Japan’s Specialists Center of Port and Airport Engineering (SCOPE), awarded on 23 January 2026. This certification follows a thorough assessment under SCOPE’s Rubber Fender Testing Environment Certification Program, which validates that the company’s testing facilities for marine rubber fenders operate with integrity and reliability. Specifically, the certification confirms that Yokohama Rubber employs a robust system designed to prevent data fraud, ensuring the trustworthiness of all test results for fenders it manufactures and sells.

These fenders serve as critical safety components, acting as cushioning buffers to protect vessel hulls from impact during harbour mooring and ship-to-ship transfers at sea. To promote safer and more secure maritime operations, SCOPE launched its certification initiative in April 2023, focusing on verifying the reliability of fender testing environments. The programme is aligned with technical guidelines from the World Association for Waterborne Transport Infrastructure (PIANC) and evaluates compliance across multiple SCOPE-defined criteria. These include adherence to static compression testing standards, the elimination of opportunities for data falsification, the integrity of statistical values in test data and the establishment of corporate systems that prevent tampering.

Yokohama Rubber’s expertise in this field dates to 1958, when it pioneered the world’s first pneumatic fender for offshore vessel berthing. Recently, the company has broadened its portfolio beyond high-performance pneumatic fenders to include solid fenders, which represent a principal segment of the fender market. This strategic expansion establishes Yokohama Rubber as a comprehensive fender manufacturer and reinforces its revenue foundation.

The achievement aligns with the company’s ongoing medium-term management plan, Yokohama Transformation 2026 (YX2026), which spans fiscal years 2024 to 2026. A key element of this strategy involves driving growth in the MB Segment by focusing resources on core domains such as hose and couplings along with industrial products. Within this framework, Yokohama Rubber aims to strengthen its product lineup and sustain strong market shares for marine products, including fenders, to secure steady profit growth in the industrial products business.

Bridgestone India Taps Punjabi Star Parmish Verma For Regional Growth Push

- By TT News

- January 27, 2026

In a strategic move to strengthen its connection with vital regional audiences, Bridgestone India has partnered with multifaceted Punjabi star Parmish Verma. This collaboration is designed to resonate deeply in North India, a crucial and rapidly expanding market fuelled by increasing vehicle ownership and a youthful demographic. Verma, a prominent cultural figure and known automobile enthusiast, aligns naturally with the brand’s emphasis on safety, reliability and performance. His authentic passion for vehicles and responsible driving complements Bridgestone’s identity as a leading mobility solutions provider.

Central to this alliance is the co-creation of engaging, music-led narratives and digital content for Bridgestone’s campaigns, leveraging Verma’s artistic talents and significant social influence. This approach recognises the powerful role of popular culture in shaping brand preferences within the region. The partnership also advances the company’s broader regional engagement goals, aiming to build deeper trust with consumers nationwide. Furthermore, it embodies the ‘Emotion’ principle of Bridgestone’s corporate commitment, which seeks to inspire excitement and deliver joy through mobility. By uniting with a figure of Verma’s reach and genuine interest, Bridgestone India fosters a more dynamic and culturally relevant dialogue with its audience.

Rajiv Sharma, Executive Director – Sales & Marketing, Bridgestone India, said, “North India is a strategically important market for us. Parmish Verma’s credibility and deep connection with audiences make him an ideal partner to represent Bridgestone. This collaboration enables us to engage meaningfully with young consumers who seek fresh, inspiring and relatable brand experiences.”

Verma said, “Bridgestone is a brand people trust for safety and performance. I’m proud to be associated with an organisation that values quality and puts customers first. I look forward to connecting with audiences in a new and meaningful way through this partnership.”

Bridgestone Americas Appoints Michele Herlein As New Chief People Officer

- By TT News

- January 24, 2026

Bridgestone Americas has appointed Michele Herlein as its new Chief People Officer. In this role, she will oversee all human resources operations across the Americas, Europe, Middle East and Africa. Her primary focus will be advancing the company's Culture 2.0 initiative, which aims to enhance teammate empowerment, collaboration and accountability.

Herlein rejoins Bridgestone with over two decades of executive leadership expertise. Her background includes previous positions within Bridgestone Americas and Bandag, Inc., centred on culture, leadership development and succession planning. Most recently, she was the Founder and CEO of CultureMax and previously served as the Chief Administrative and Human Resource Officer at Barge Design Solutions. She is also a published authority on creating high-performance organisational cultures. Beyond her corporate work, Herlein is a co-founder of Impact100 Nashville, a philanthropic women’s collective that has awarded more than USD 1.2 million in grants to area nonprofits.

Scott Damon, Bridgestone West CEO and Group President of Bridgestone Americas, said, “I am excited to welcome her back to Bridgestone, recognising the perspective and presence she will add to our West leadership team, the HR function and the broader organisation.”

Comments (0)

ADD COMMENT