Orion Launches Bio-Circular Carbon Black For Sustainable Coatings

- By TT News

- April 30, 2025

Global speciality chemicals company Orion S.A. has launched a new bio-circular carbon black called ECOLAR 50 POWDER to provide coatings manufacturers with a new solution for more sustainable coatings.

ECOLAR 50 POWDER, which is entirely based on bio-circular feedstock, has coloristic qualities that are on par with those of ordinary speciality carbon blacks and includes 100 percent biogenic raw material according to 14C analysis. The coloristic qualities of ECOLAR 50 POWDER, a low to medium colour furnace black, offer moderate tinting strength and medium jetness in mass tone applications. ECOLAR 50 POWDER offers equivalent coloristic performance for full-tone and tinting applications, as well as comparable wetting and dispersion characteristics to conventionally manufactured low-colour furnace blacks.

ECOLAR 50 POWDER outperformed other common specialist carbon blacks in achieving medium jetness in a solvent-borne alkyd/melamine stoving enamel system. It created a similar neutral undertone as well. When tested in a water-borne 1K PU coating system, ECOLAR 50 POWDER created a more neutral undertone and jetness that was on par with other regular speciality carbon blacks.

Tilo Lindner, Vice President Global Marketing – Speciality Carbon Black, Orion, said, “We’re leading the way in advancing carbon black to meet increasing industry demands for sustainable products. ECOLAR 50 POWDER enables coatings formulators to develop truly sustainable products in all kinds of coatings applications.”

Pyrum Rebrands Recycled Materials To Strengthen Market Identity

- By TT News

- March 07, 2026

Pyrum Innovations AG has announced an immediate update to the nomenclature of its recycled material outputs as part of a strategic effort to reinforce its brand identity and underscore the distinctiveness of its offerings. The company’s thermolysis oil, formerly referred to as recycled oil, will now be designated TTO (ThermoTireOil). Similarly, what was previously known as recovered Carbon Black (rCB) will adopt the new name TTB (ThermoTireBlack).

This decision stems from inconsistencies observed across the broader market for recycled commodities. Materials sold under generic labels such as rCB or pyrolysis oil often vary significantly in composition, largely because they may contain residual additives or lack standardisation. In the case of rCB, for instance, the presence of inorganic elements from tyres can lead to blends that are unsuitable for certain high-performance applications. Pyrum’s output, by contrast, is produced through its patented thermolysis technology, which yields materials with a consistent and well-defined makeup. The new names are intended to reflect this precision and set them apart from less uniform alternatives.

The underlying production process remains centred on breaking down end-of-life tyres into their constituent elements. TTB has already entered series manufacturing in the tyre industry and is gaining recognition for use in products such as conveyor belts, seals, and protective coatings. TTO, meanwhile, functions as a renewable input for polymers used in clothing, automotive components and food-safe packaging.

Rollout of the new terminology begins at once and will be phased into all technical records, official certifications and customer communications. Although the labelling is new, the formulations and quality levels of the products themselves are unchanged.

Pascal Klein, CEO, Pyrum Innovations AG, said, “Our products are the result of years of development and intensive research. With the new designations TTO and TTB for our oil and our rCB, we make it clear that these are unique materials obtained from our unique thermolysis process.”

KRAIBURG TPE Secures EcoVadis Gold For Second Consecutive Year

- By TT News

- March 06, 2026

KRAIBURG TPE has earned gold medal from EcoVadis for the second consecutive year. This recognition reflects the performance of the company’s entire global operations, which collectively achieved this distinguished honour. The company posted new peak scores across all four evaluation categories, which include environmental impact, labour and human rights, ethical conduct and sustainable sourcing. Ranking in the 98th percentile, KRAIBURG TPE now stands among the top two percent of all companies rated by EcoVadis globally, reinforcing its status as a frontrunner in responsible corporate practices.

Within the plastics sector, sustainability has evolved into a fundamental driver of success. Growing public attention now extends beyond isolated topics, calling instead for businesses to offer clear and reliable sustainability reporting. Measurable indicators that track advancements and allow for objective comparisons across industry peers have thus become indispensable.

Having evaluated over 150,000 businesses, EcoVadis has cemented its role as one of the most trusted frameworks for assessing corporate sustainability. The benchmarks applied by the Paris-based organization across its categories are both rigorous and comprehensive. Given this demanding standard, KRAIBURG TPE’s 2022 achievement of a silver award in its debut year was particularly meaningful.

In 2025, the company reached a new milestone by receiving its first gold medal covering all global facilities, a testament to inter-site collaboration and the dedication of its entire workforce. This distinction was reaffirmed during the scheduled reassessment in January 2026, accompanied by even higher marks in every category. Such ongoing improvement demonstrates the company’s steadfast commitment to advancing its sustainability objectives consistently across international operations.

Oliver Zintner, CEO, KRAIBURG TPE, said, “For us, this second Gold Award is confirmation in many respects of the extraordinary achievements we have made in the field of sustainability in the past years. On the one hand, it demonstrates how strong our position is in international comparison. But above all, the award emphasises how continuously and persistently we pursue our sustainability goals in all categories. Results like that are not at all a matter of course in our competitive environment. They only become possible because our colleagues at all sites worldwide are closely working together in a partnership-based manner.”

Michael Pollmann, Sales & Marketing Director EMEA, said, “In addition to product quality, price and delivery reliability, sustainability criteria are a more and more important factor for our customers’ purchase decisions. The EcoVadis award represents the consistency and transparency with which we implement our sustainability promises. It is a relevant strategic competitive factor and is gaining in importance, particularly in view of increasing legal requirements in fields such as supply chain assessment.”

Pyrum Secures ISCC EU Certification For Tyre-Derived Oil

- By TT News

- March 06, 2026

Pyrum Innovations AG has achieved ISCC EU certification for its thermolysis oil from end-of-life tyres. This confirms alignment with EU Renewable Energy Directives RED II and RED III, allowing the oil's use across the European Union as sustainable feedstock for biofuels and other renewable energy sources.

This endorsement represents a pivotal advancement in Pyrum's industrial scaling. By bridging circular economy principles with a defined energy sector, the oil is now eligible within a regulatory environment essential for sustainable fuel growth in Europe. Consequently, market expansion is enhanced, especially in biofuel, bioliquid, biomass fuel and co-processed sectors.

The ISCC EU certification is a global standard for verifying sustainability and transparency. It assures that ecologically sensitive areas are safeguarded, emissions minimized across the value chain and all material flows traceable. It guarantees adherence to all sustainability criteria mandated by RED III. As part of verification, greenhouse gas emissions are validated according to the GHG Protocol.

Politically, this certification unlocks significant application for secondary raw materials, converting problematic waste into a resource supporting decarbonisation goals. Pyrum demonstrates a scalable European model integrating waste management, resource recovery and energy generation.

Economically, the timing is critical as Pyrum expands capacity. Access to regulated biofuel markets strengthens commercial resilience by lessening reliance on traditional recyclate markets. This diversification enhances financial predictability during a phase where securing capacity and scaling operations are paramount.

Pascal Klein, CEO, Pyrum Innovations AG, said, “ISCC EU certification is more than a formal achievement for us. It provides access to a regulated market environment that is central to Europe’s decarbonisation strategy. At the same time, it strengthens the resilience of our commercialisation strategy as we expand capacity and reduces our dependency on individual recyclate markets.”

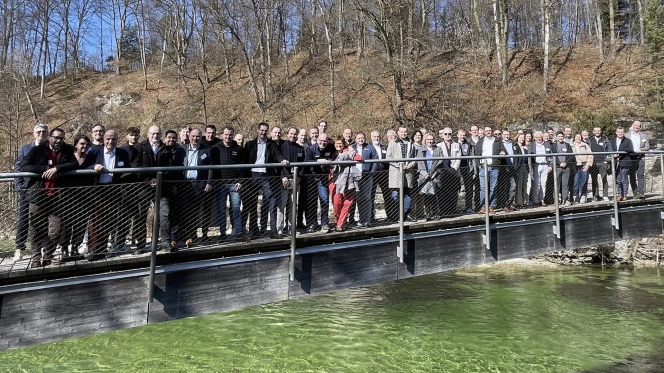

European Tyre Industry Gathers In Austria For 6th AZuR Partner Meeting

- By TT News

- March 06, 2026

The 6th AZuR Partner Meeting convened over 70 participants from industry, small and medium-sized enterprises, trade, politics and academia on 26 and 27 February 2026 in Upper Austria. The event was hosted by KIAS Recycling GmbH, the operator of Austria’s sole used tyre recycling plant, at the Alte Fabrik event centre. The gathering brought together stakeholders from across the European tyre and recycling sector for a programme of presentations, workshops and discussions. The central aim was to devise forward-thinking solutions and projects to enhance retreading alongside mechanical and chemical recycling processes.

Christina Guth, the AZuR network coordinator, expressed her satisfaction with the high level of personal engagement demonstrated by partners from across Europe. She noted that expert presentations injected fresh energy and the ensuing dialogues generated promising concepts for expanding the tyre circular economy. She extended particular gratitude to the KIAS Recycling team for their thorough preparation and organisation, which made such a substantial event possible.

The technical proceedings commenced after a welcome from representatives of KIAS Recycling, the wdk and AZuR. Professor Holger Hoppe from TH Ingolstadt delivered an engaging presentation centred on the future of the circular economy, illustrating how the combination of novel business models, regulatory measures and cross-disciplinary teamwork can propel the necessary transformation. A subsequent networking session, guided by coordinator Anna-Maria Guth, reviewed the previous year's milestones, including political engagement at various governmental levels, scientific partnerships, trade fair participation and international exchanges.

A significant portion of the meeting was devoted to updates from AZuR’s three project groups. The retreading group is intensifying its political advocacy regionally and boosting its profile at major trade fairs. The mechanical recycling group is prioritising collaborations and involvement in municipal tenders and specialist conferences. Meanwhile, the chemical recycling group is concentrating on completing masterbatch initiatives, developing practical product applications and clarifying the distinction between pyrolysis and simple incineration.

The visit to KIAS Recycling’s facility stood out as a key highlight. Partners were led through the plant in small groups, observing firsthand the modern processes of tyre recycling, from intake and treatment to the high-value application of recovered materials. This tour effectively demonstrated that certified waste management and recycling infrastructure are fundamental to a successful tyre circular economy.

Comments (0)

ADD COMMENT