Turning Old Tyres Into Urban Art

- By Sharad Matade & Gaurav Nandi

- August 21, 2025

In a country grappling with mountains of waste and a pressing need for sustainable solutions, one designer in Kanpur is quietly rewriting the rules of urban innovation. Vaishali Biyani, a former recruiter-turned-upcycler, has built a company that transforms discarded truck tyres into striking urban furniture, art installations and public park infrastructure. Her start-up, De’Dzines, operates at the unlikely intersection of circular economy, rural employment and high-concept design. In spaces as diverse as five-star hotels and snowy army outposts, her creations endure and inspire. What began as a curiosity about tyre waste has grown into a bold, scalable vision for environmental reinvention.

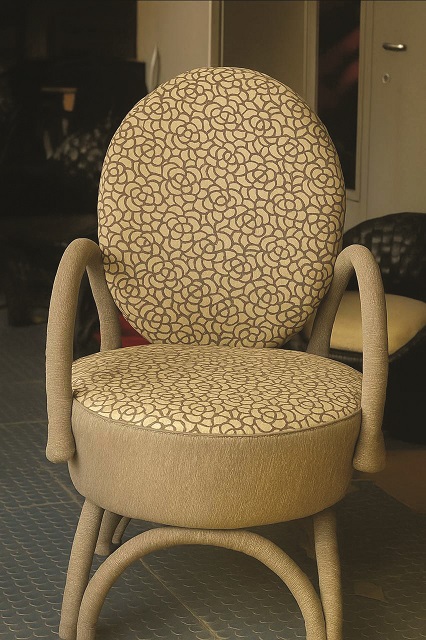

In the snow-clad silence of Siachen, India’s highest military outpost, stands a curious piece of furniture made not of wood, nor of steel but from discarded tyres. Two years since it was installed, the chair hasn’t warped, cracked or budged. Even in snowstorms, the furniture is standing strong. It was one of many quiet validations for a project that, to many, still sounds improbable: transforming end-of-life tyres into swings, sculpture parks and stylish indoor planters.

On the dusty fringes of Kanpur, a former industrial powerhouse now known more for its mountains of discarded waste than for its textiles, an unexpected kind of manufacturing is quietly reshaping public parks and luxury hotels. The raw material? Old truck tyres.

At the heart of this transformation is an unlikely entrepreneur. Once immersed in the startup buzz of Delhi, she spent over a decade building a successful recruitment company. But a twist of fate took her to Kanpur, where she spotted something that others had learned to ignore: waste.

“Waste was everywhere, from roads, outside factories to back alleys. But tyres stood out. They were built to last and nobody knew what to do with them,” said Vaishali Biyani, Founder of De’Dzines.

Her shift from the digital corridors of Delhi to the tyre-strewn lanes of Kanpur was anything but planned. “I had no intention of starting over. My recruitment firm was doing well. But when I relocated in 2017, I began noticing the sheer scale of unutilised waste, especially tyres,” she admitted.

What followed was a period of grassroots immersion. By day, she continued recruitment work. By night, she sat with tyre scrap dealers, learning the material inside out. She recalls walking through filthy lanes where tyres lay in heaps, asking questions most dealers never expected.

In 2019, she registered her company De’Dzines and formally launched commercial operations in 2021. Her goal was to upcycle truck tyres into handmade furniture, planters and urban sculptures.

The choice of truck tyres was deliberate as they comprise better rubber composition, more wire and stronger polymers.

The early days weren’t easy. Setting up in Kanpur came with its own cultural and logistical hurdles. “People here had never heard of upcycling.

They thought I was collecting garbage, and when I tried to hire people, nobody wanted to work with tyres. Even explaining the concept was a battle,” recalled Biyani.

Her 20,000-square-foot workshop in Kanpur became ground zero for a new type of production rooted in low-tech and high-ingenuity processes. “We use small tools, not big machines. Everything is handmade, from cutting, cleaning to polishing. Each product is crafted by a team of 15 full-time workers, all from nearby villages. For larger orders, the team expands to 50,” explained Biyani.

She recalled that hiring was a nightmare. Hence, she trained locals, most of whom had never worked in manufacturing. Today, they handle everything from wire removal to final finishing.

CHANGING PERCEPTIONS

The idea didn’t start in a studio but in scrap yards and municipal back alleys, where tyres lay heaped, burnt, buried and forgotten. Starting with a handful of used tyres, the founder and his lean team began crafting swings and planters by hand. Today, the company consumes between 10–12 tonnes of tyres monthly, rising significantly during major government projects.

“We usually do two big waste to wonder parks each year. If it’s a two-acre project, it could require tonnes of tyres. We’ve done parks where the government provided tyres themselves; we just deducted that cost from the tender,” said Biyani.

She added that in these early partnerships, the team didn’t have the luxury of choosing tyre types. But now, they get to select what is needed. The company now focuses on nylon-based truck tyres, especially from buses and transport bodies.

Changing consumer perception was perhaps the biggest challenge as tyres are dirty and smelly. People don’t even want to touch them. So she launched a direct-to-consumer (D2C) model to test market acceptance. The Covid-19 lockdowns, surprisingly, helped.

“Everyone moved online. I started listing products on Amazon before I even had a website. The response was overwhelming. People liked what they saw and left great reviews. That gave us confidence to double down,” averred Biyani.

But sustainability messaging wasn’t the silver bullet as Indians don’t pay extra for eco-friendly, she contended. The company had to position the products for its durability, aesthetics and value.

She recalls the initial scepticism from customers divulging, “We had people asking that won’t this smell or will it leave black marks. So we added multiple layers of polish, built a hygiene protocol and offered an easy return policy. If you didn’t like the product, you could send it back. No questions asked,” she explained.

The strategy worked. The brand slowly built a reputation not just for environmental responsibility but also for reliability and craftsmanship.

UPCYCLED PRODUCT

At De’Dzines, each tyre begins its second life with a rigorous cleaning process. Steel wires are removed, often manually. Then comes cutting, which is a precision job to ensure the structural integrity of the product. After shaping, the rubber is treated with safe, non-toxic polish and reinforced with recycled wood or steel depending on the final design.

“The design philosophy is simple. Form follows function but beauty matters. We don’t want the product to scream ‘I’m made of waste’. We want it to feel like something you’d be proud to place in your home or office,” she explained.

Some products take two days to complete. Others, like swing seats or large benches, can take over a week. The company isn’t chasing mass production but chasing quality, story and purpose.

Some products take two days to complete. Others, like swing seats or large benches, can take over a week. The company isn’t chasing mass production but chasing quality, story and purpose.

While European and Australian companies offered to export tyre scrap to her for free, she refused. “The logistics defeat the purpose. Sustainability isn’t just about materials; it’s also about carbon footprint. Why ship tyres across oceans when Uttar Pradesh is full of them,” said Biyani.

She signed MOUs with municipal corporations across Agra, Lucknow, Prayagraj and Gorakhpur. These urban bodies provided used tyres from fleet vehicles.

While scrap tyres are generally expensive in India, this circular sourcing model keeps costs manageable. “The tyre scrap market in India is fragmented, expensive and full of middlemen. That’s why we prefer working directly with municipal bodies,” noted Biyani.

For projects with unpredictable demand, she still sources from the open scrap market.

BACKYARDS TO FIVE-STAR LOBBIES

As public confidence grew, so did the scale of projects. De’Dzines moved from retail to B2B, then to government partnerships. One milestone was supplying planters to the Shangri-La Eros Hotel in Delhi. “The hotel placed them in every room and throughout the gardens. That proved we could pitch to luxury hospitality,” said Biyani.

Today, De’Dzines has designed and completed over 10 public parks in partnership with local governments. It handles everything from concept to installation. It’s no longer just about products but transforming spaces.

In one project near Prayagraj, she repurposed over 4,000 tyres to create an entire play zone that included benches, see-saws, tyre walls and garden edges. “We turned waste into wonder. The joy on children’s faces is our biggest endorsement,” quipped Biyani.

For a country drowning in waste yet starved for sustainable innovation, De’Dzines offers a blueprint that blends environmental purpose with rural employment and scalable design. Her journey is also a quiet rebuke to the idea that innovation only happens in technological hubs.

“I didn’t come here to start a recycling revolution. I was just curious about where tyres go when they die. That one question changed everything,” she contended.

“I didn’t come here to start a recycling revolution. I was just curious about where tyres go when they die. That one question changed everything,” she contended.

As she trains her team for their next urban park project, surrounded by stacks of discarded rubber, the message is clear that even the dirtiest waste can have a second life with beauty and durability.

HANDMADE, YET SCALABLE

One might imagine such a business struggling with scale. After all, each piece, be it a sculpture or a chair, is largely handmade. But ingenuity, it turns out, is as core to the company’s identity as sustainability.

A telling moment came during an export order. A client requested 500 customised planters with a 20-day delivery timeline. “It wasn’t our design. It was theirs and very detailed. So we built a single mould for it, trained 50 people and finished in 15 days instead of 20,” recalled a confident Biyani.

This success paved the way for future scale-ups. The team has since developed moulds for several recurring products while still retaining flexibility for custom projects.

“We now know how to train fast, hire locally and deliver in volume. It’s a hybrid of craft and light manufacturing,” she added.

Alluding to working with different government bodies, Biyani spoke candidly about the public sectors’ promise and bureaucracy. “Municipal corporations are straightforward. We sign a simple MOU that lets us collect tyres for two or five years. In return, we give them a rate list for furniture or sculptures when needed. It’s simple and direct,” she contended.

Working with state transport undertakings like BEST or DTC, however, is a different story as their procurement is through massive tenders.

So, for now, she prefers to work with cities like Prayagraj, where the team completed nine junction designs and two parks in just 45 days.

LOOKING AHEAD

Much of the company’s growth has come not from sales teams but from serendipity and design.

One of the most fruitful connections came via social media, when a CSR head from Bridgestone discovered the team’s Instagram posts. Today, the company is working with Bridgestone on a multi-year sculptural design project in Pune.

Her vision now extends beyond upcycling. “We’re exploring modular designs that can be assembled onsite for large-scale installations,” she revealed. There are also plans to set up satellite workshops in other parts of UP using the same village employment model.

Her vision now extends beyond upcycling. “We’re exploring modular designs that can be assembled onsite for large-scale installations,” she revealed. There are also plans to set up satellite workshops in other parts of UP using the same village employment model.

Eventually, she wants to export as she believes that the products should sit in parks in Dubai or public plazas in Europe. Not because they’re Indian or upcycled but because they’re beautiful and built to last.

As demand grows, the company is moving into newer segments. The next frontier is hospitality.

“We’re now working with luxury hotels, resorts and even army cantonments. Our products survive storms in Siachen. They survive monsoons in Goa. That’s our pitch: sustainable, durable and different,” quipped a cheerful Biyani.

She’s also gearing up for a major hospitality exhibition in Greater Noida from 3–6 August, where the team will launch a new line of indoor furniture made from upcycled tyres.

But challenges remain; chief among them is pricing. “A virgin plastic chair is cheaper than our tyre-based one. Convincing someone to pay a premium for sustainability is our biggest hurdle,” she contended.

There is a poetic irony in transforming black industrial waste into playful swings and public sculptures. It is perhaps this unlikely fusion of function and imagination that distinguishes the designer.

In places like Prayagraj, Pune and even Siachen, tyres are no longer confined to roads; they are finding new meaning as symbols of transformation.

For a small design company with ambitious ideas, it seemed that the path forward might indeed be paved, quite literally, with rubber.

Zeon And Visolis Sign Binding Term Sheet To Advance Bio-Isoprene And SAF Commercialisation

- By TT News

- February 16, 2026

Zeon Corporation and Visolis Inc. have formalised their partnership by signing a binding term sheet, marking a pivotal advancement in the commercialisation of bio-based isoprene monomer and sustainable aviation fuel (SAF).

This collaboration, which now moves from technology verification towards project implementation, is built upon the progress made since their initial memorandum of understanding in March 2024 and the subsequent joint feasibility study announced in April 2025. Bio-based isoprene monomer serves as an essential component in the production of synthetic rubbers and various other materials, while SAF is increasingly recognised as a critical next-generation fuel for reducing carbon emissions within the aviation industry.

The newly established term sheet outlines a foundational agreement on the key elements required for a final investment decision. These include defining the business structure and the respective roles of each company, establishing technology and development strategies and advancing detailed engineering for the proposed production facility. Furthermore, the agreement covers the evaluation of potential sites, the process for engaging with suppliers, securing necessary regulatory approvals and planning the financing pathway.

The envisioned facility is set to commence commercial-scale output after successfully demonstrating mass production capabilities for biomass-based isoprene and SAF, utilising Visolis’ proprietary technology. Both companies are now committed to expediting the path to full-scale production and ensuring a steady supply of these sustainable products to the global market.

Zeon Backs Chemify To Accelerate Digital Chemistry Innovation

- By TT News

- February 12, 2026

Zeon Corporation has deepened its commitment to digital chemistry through a strategic investment and partnership with Chemify Limited, secured via its corporate venture arm Zeon Ventures Inc. Chemify, a growth-stage UK enterprise, is reshaping molecular research by integrating digital tools with automated laboratory systems. Its proprietary Chemputation technology translates molecular targets into executable chemical code, which operates directly on robotic platforms to complete integrated Design–Make–Test–Analyze cycles without manual intervention. This closed-loop automation allows Chemify to explore previously inaccessible areas of chemical space while reducing the timeline from concept to synthesized compound by up to tenfold.

A cornerstone of Chemify’s capability is its recently inaugurated Chemifarm in Glasgow – one of the most sophisticated automated facilities in the world for molecular design and construction. The facility enables accelerated iteration and autonomous synthesis of novel small molecules, converting chemical code into tangible compounds with unprecedented efficiency. These advances are critical for developing functional, synthesisable molecules that can contribute solutions to urgent global issues spanning public health, energy efficiency and environmental protection.

Zeon has been at the forefront of adopting digital methodologies in chemical R&D, recognising their transformative potential from an early stage. This investment is positioned to strengthen Zeon’s internal digital chemistry efforts and catalyse the invention of novel materials capable of addressing complex societal needs. The move aligns with Zeon’s STAGE30 corporate strategy, which targets a rise in revenue contribution from four key growth sectors – Mobility, Healthcare and Life Sciences, Telecommunications and Green Transformation – to 48 percent by fiscal 2028. By backing pioneering enterprises and cultivating advanced materials, Zeon continues to advance its dual vision of a sustainable planet and a secure, progressive society.

- Rubber Board Of India

- Rubber Producers’ Societies

- Sulphur Dusting

- Powdery Mildew

- Rubber Plantations

- Rubber Board Subsidy

Rubber Board Announces Sulphur Dusting Subsidy For Rubber Producers

- By TT News

- February 09, 2026

The Rubber Board of India has announced the opening of an application window for financial aid for sulphur dusting to combat powdery mildew disease in rubber plantations for the year 2026. The scheme is open to all Rubber Producers’ Societies (RPS) operating in both traditional and non-traditional growing regions.

From 10 to 20 February 2026, eligible societies must submit their applications online through the 'ServicePlus' portal on the official Rubber Board website. Societies requiring help with the submission process are advised to contact their nearest Rubber Board regional office or field station, or to consult the board's website for further guidance.

French Recognition Of TPO Bolsters Pyrum's Circular Economy Model

- By TT News

- February 09, 2026

Pyrum Innovations AG has welcomed the official recognition by French authorities on 17 January 2026, which classifies tyre pyrolysis oil (TPO) as a legitimate raw material for the chemical sector. This pivotal regulatory milestone for pyrolysis oil derived from end-of-life tyres substantially enhances the product’s integration into established chemical value chains. It also provides greater predictability for future purchase and partnership frameworks, thereby accelerating the development of industrial material cycles.

For Pyrum, which processes scrap tyres through pyrolysis to recover pyrolysis oil, industrial carbon black and steel, this decision underscores the critical need for standardised and reliable regulatory conditions. Such clarity is fundamental for scaling investments, production volumes and supply chains, particularly as the chemical industry and circular economy converge. The establishment of clear product categories is essential to ramp up the market for high-quality recycled raw materials.

The company remains committed to tracking further developments in France and the wider European dialogue regarding the classification and application of recycled feedstocks. Pyrum’s overarching objective is to expand industrial-scale recycling solutions for scrap tyres. This regulatory progress directly supports the company’s mission to secure long-term, quality-assured supply agreements with partners across the chemical industry, thereby advancing a more sustainable and circular economic model.

Pascal Klein, CEO, Pyrum Innovations AG, said, “The decision in France is an important step for the industrial use of pyrolysis oil from waste tyres. It supports a trend that we are seeing in many markets, where the chemical industry is seeking reliable, technologically robust and clearly classified alternative raw materials.”

Comments (0)

ADD COMMENT