- INDIAN TYRE INDUSTRY

- TYRE RETREADING

- BIS STANDARDS

- IS 15704

- ECE R109

- CIRCULAR ECONOMY

- MSME CHALLENGES

- AUTOMOTIVE REGULATION

- CARBON REDUCTION

- FREIGHT

- LOGISTICS

Retreading Hangs In Balance Over Regulatory Conundrum

- By Gaurav Nandi

- December 30, 2025

Tyre retreading

A population of over 1.4 billion people catapulting into the world’s third largest automobile market with four million trucks plying across a road network of 6.3 million kilometres supported by a USD 13.4 billion tyre market and a mining sector contributing around 2–2.5 percent of the country’s GDP demonstrate the strength of India’s automobile, freight and tyre sectors.

The story doesn’t end there as the Central Government adopts a strategic approach on reducing carbon emissions across these verticals, especially automobile and tyres, with targets such as the Net Zero Carbon Emissions by 2070, battery electric vehicles target by 2030, zero-emission truck corridors, Extended Producer Responsibility for the tyre sector; the list just goes on.

Amidst all such statistics and targets, a silent spectator remains the old and varied sector of tyre retreading. In a recent news story reported by Tyre Trends, the Indian Tyre Technical Advisory Committee (ITTAC) had made a proposal to Tyre Retreading Education Association (TREA) for mandating certain standards that will improve the quality of retreads. ITTAC has made recommendations to the BIS committee. TREA is part of the same committee. ITTAC and TREA are recommending different standards.

These standards included BIS retread standards, namely IS 15725, IS 15753, IS 15524 and IS 9168. The ITTAC had partially aligned Indian requirements with ECE R109, the European regulatory benchmark.

In a reply to the proposal, which was accessed by Tyre Trends, TREA urged the Indian Tyre Technical Advisory Committee to seek a deferment or non-applicability of BIS standard IS 15704:2018 for retreaded commercial vehicle tyres, warning that mandatory enforcement could cripple the sector.

In the letter, TREA argued that IS 15704:2018 is largely modelled on new tyre manufacturing norms and is technically unsuitable for retreading, which is a restoration and recycling process.

The standard mandates advanced laboratory tests such as spectrometer-based rubber analysis, endurance testing and compound uniformity checks, requirements that most retreading units, particularly small and medium enterprises, are not equipped to meet

The association highlighted that even large retreaders lack the infrastructure and skilled manpower needed for BIS-grade testing, while the sheer number of retreading units would make inspections and certifications operationally unmanageable for regulators.

TREA warned that compliance costs linked to machinery upgrades, audits and quality control could force 70–80 percent of units to shut down, leading to job losses, higher fleet operating costs and adverse environmental outcomes due to reduced recycling

Instead, TREA proposed that BIS prioritise retreading-specific standards such as IS 13531 and IS 15524, which focus on materials, process control, safety and quality consistency.

The body has also called for a phased transition roadmap, MSME support and industry training before any stricter norms are enforced, stressing that abrupt implementation would undermine the sector’s role in India’s circular economy.

The conundrum

India has a total of 36 administrative divisions comprising 28 states and 8 union territories. The tyre retreading sector has been continuously supporting circularity goals since the early 1970s across the world’s largest economy without getting mainstream recognition.

Even after five decades in service, the industry battles different bottlenecks including fragmentation, manpower shortage, tax pressures brought about by the recent GST revisions and now the implementation of such standards, just to name a few.

The sole practice that can simultaneously reduce carbon emissions from tyres and extend tyre life is assumed the nemesis of an ‘infamous and dangerous practice’ in some states of the country.

However, the industry has been drawing its techniques and quality parameters from the world’s oldest retreading economy, Europe.

“Big retreaders in India already have the necessary processes in place that conform to IS 15524 standards. However, as the standard is not yet mandated, we have voiced support for it because it is process-oriented and outlines how retreading should be carried out, including buffing and building procedures,” said TREA Chairman Karun Sanghi.

He added, “This standard focuses on how the work is done rather than imposing product-level testing that cannot be practically implemented. The current debate on IS 15704 stems from it being fundamentally incompatible. The standard includes requirements such as sidewall marking and destructive testing of retreaded tyres, which are impractical in a retreading environment where each tyre differs in brand, size, application and usage history,” he added.

Destructive testing, he argued, assumes uniform batch sizes. In retreading, where every casing is unique, testing even a single tyre would mean destroying finished products without yielding representative results. Applying such a framework would effectively require the destruction of every tyre in a batch, making compliance unviable.

“We have submitted our response to ITTAC and are awaiting feedback from the committee. We remain open to continued dialogue and will engage further once the committee responds to our submission,” said Sanghi.

According to him, a typical retreader processes about 300 tyres a month across multiple brands including MRF, JK Tyre, Apollo and Michelin and applications ranging from buses and trucks to mining vehicles. These casings vary widely in load cycles, operating conditions and duty patterns, often across several models from the same manufacturer.

The committee has cited European standard ECE R109, but Sanghi points to structural differences: “Europe is a global retreading hub where tyre manufacturers such as Michelin and Bridgestone dominate operations, collect their own tyres, retread them and return them to fleets, making batch-based destructive testing relevant. A similar model exists in US, where large tyre companies lead retreading and largely self-regulate without a single overarching standard. The Indian scenario is different, especially with a fragmented market.”

He stressed that the industry is not opposed to standards but to those that cannot be practically applied, warning that adopting European manufacturing-oriented norms without accounting for India’s market structure and operating realities would be counter-productive.

The debate is no longer about whether standards are needed but whether they are fit for purpose. Without accounting for India’s fragmented retreading ecosystem, enforcing impractical norms could dismantle a circular industry in the name of compliance.

- Bridgestone India

- Bridgestone Select Stores

- ENLITEN Technology

- Bridgestone Turanza 6i

- Bridgestone Dueler All-Terrain A/T002

Bridgestone India Expands Assam Footprint With Two New Select Stores In Guwahati

- By TT News

- February 17, 2026

Bridgestone India has expanded its retail network in Assam with the opening of two new Bridgestone Select Stores in Guwahati. The inauguration ceremony was led by Rajiv Sharma, the company’s Executive Director of Sales and Marketing. One of the newly established outlets, Kamrup Tyres, is situated at 89 No. Dadara Gaon Panchayat, Damdama-Kulhati Road, while the other, The Wheelz Shoppe, is located near the Jaiswal Weigh Bridge on NH-37 in Boragaon.

These Bridgestone Select Stores are conceived as comprehensive destinations for tyre and wheel care. They are designed to provide customers with not only premium products but also professional advice, state-of-the-art equipment and services that prioritise safety, comfort and enduring vehicle performance. This expansion reflects the company’s strategic response to the increasing regional demand for dependable and superior tyre solutions. The new locations aim to serve as convenient hubs for passenger vehicle owners in the Guwahati area, offering a full spectrum of tyre-related services under one roof.

Motorists visiting these stores will have access to Bridgestone’s latest premium tyre offerings. This includes the Turanza 6i, which incorporates ENLITEN technology to deliver enhanced comfort, greater efficiency and compatibility with electric vehicles. Also available is the Dueler All-Terrain A/T002, a tyre renowned for its reliable performance on both regular roads and more challenging off-road terrains.

The establishment of these two outlets underscores Bridgestone India's ongoing commitment to growing its customer-focused retail presence. Through this initiative, the company continues to bring its globally recognised tyre solutions and services closer to motorists across the country.

Sharma said, “Assam continues to be an important market for Bridgestone. The opening of these two Select Stores in Guwahati reflects our commitment to offering customers easy access to premium products and trusted services. Our focus is on building long-term relationships by delivering safety, quality and a consistently good experience.”

Pirelli Brings Full Rainbow Of Compounds As F1 Testing Resumes In Bahrain

- By TT News

- February 16, 2026

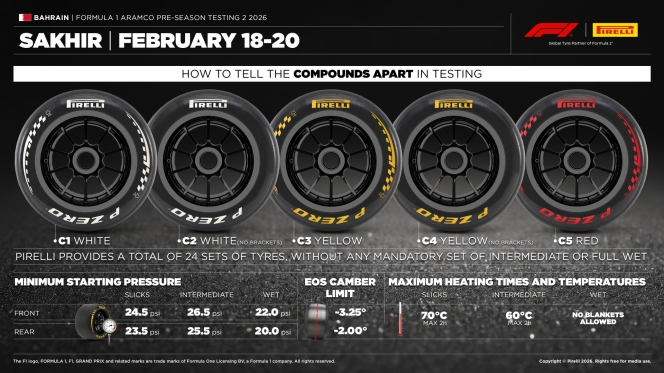

Formula 1 is set to resume on-track action in Bahrain for the second pre-season testing session, beginning 18th February and running through 20th February. This three-day event marks the final opportunity for teams to evaluate their cars ahead of the championship opener, building on the data gathered during the previous week's running.

A significant change for this test is the expanded tyre availability from Pirelli. While the initial session was restricted to the three hardest compounds, teams have now selected 24 sets from the full range of five dry-weather options. They are also permitted to carry over any tyres used for nine laps or fewer during the first test. An analysis of team selections reveals varied strategic approaches. The C3 and C2 compounds emerged as the most popular choices, requested by 10 of the 11 teams. Mercedes was the exception, opting to remain solely with the hardest compounds.

McLaren, Ferrari, Racing Bulls, Audi and Haas broadened their selection by including the C4. In contrast, Red Bull, Alpine, Williams and Aston Martin leaned towards softer specifications. The Visa Cash App RB squad confined its choices to the C2, C3 and C4, whereas Alpine and Williams also incorporated the softest C5 compound. Aston Martin adopted a unique strategy, selecting exclusively the three softest options: the C3, C4 and C5. Notably, incoming team Cadillac distributed its requests across the entire spectrum, making it the only entrant to secure at least one set of every dry compound.

Daily running is scheduled from 10:00 to 19:00. To aid identification, Pirelli has implemented a special colour-coding system for this test. The C1 and C2 compounds will feature white logos, the C3 and C4 will display yellow and the C5 will be marked with red. To differentiate the two compounds sharing the same colour, the harder of the pair will incorporate a distinctive chequered flag pattern on its sidewalls. Consequently, the C2 and C4 will be the only compounds without this additional decoration, bearing only the standard Pirelli and P Zero logos.

Conti Hybrid HT 5 Trailer Tyre Completes Continental's Hybrid Family For Regional Haulage

- By TT News

- February 16, 2026

Continental has unveiled the Conti Hybrid HT 5, a new trailer tyre that completes its fifth-generation hybrid tyre family designed specifically for regional freight transport. This launch provides fleet operators with a fully coordinated tyre solution for steering, drive and trailer axles, all engineered to handle the rigorous demands of distribution transport. These operations often involve a challenging mix of inner-city manoeuvring, highway cruising and occasional light off-road driving.

The new Conti Hybrid HT 5 was developed to address the specific pressures of daily regional logistics, including frequent stop-and-go traffic, navigating tight urban streets and managing variable load weights. According to Hinnerk Kaiser, Head of Product Development for Bus and Truck Tyres at Continental, this tyre model integrates safety, operational efficiency and robustness to support dependable and economical fleet performance under fluctuating conditions. The trailer tyre delivers a 15 percent increase in mileage over its predecessor, the Conti Hybrid HT 3+, leading to fewer replacements. For a fleet operating 80 trailers covering 110,000 kilometres each annually, this translates to saving roughly 32 trailer tyres per year, along with reduced labour, storage and procurement costs.

Beyond durability, the tyre contributes to lower fuel consumption thanks to its optimised rolling resistance, a critical factor given that tyres can constitute more than half of a commercial vehicle’s operating expenses. This efficiency also brings environmental advantages by decreasing raw material use and cutting CO2 emissions throughout the production chain. The Conti Hybrid HT 5 excels in wet and cold conditions, achieving a B rating for wet grip on the EU tyre label. This performance stems from a new tread compound and a redesigned pattern featuring zigzag centre grooves and 2D pocket sipes, which maintain reliable traction even as the tread wears down. The design also ensures even pressure distribution for stable braking on slippery surfaces. Additionally, it holds a top A rating for external rolling noise, helping to reduce sound pollution.

With the arrival of the HT 5, Continental now offers a unified technological approach across all axle positions for regional transport. The Conti Hybrid HS 5 provides steering precision and comfort, while the Conti Hybrid HD 5 delivers strong traction and consistent braking for drive axles. The new HT 5 rounds out the lineup for trailer axles with its stability, rugged build and adaptable grip. All Generation 5 tyres share a focus on extended mileage and long-term performance, featuring an optimised casing suitable for multiple retreading cycles and embedded RFID sensors for digital tracking. The Conti Hybrid HT 5 will launch in March in sizes 385/65 R22.5 and 385/55 R22.5, with additional sizes expected by 2027. These tyres come ready for integration with the ContiConnect digital management system via pre-installed sensors.

Bridgestone And ADRA India Join Forces To Rehabilitate Punjab Schools Devastated By 2025 Floods

- By TT News

- February 16, 2026

In the wake of the devastating floods that struck Punjab in August 2025, a strategic partnership between Bridgestone and ADRA India successfully restored educational infrastructure and learning continuity across 20 government schools in the Gurdaspur district. The natural disaster had inflicted widespread damage on school buildings, with sanitation systems rendered inoperable, while countless students lost access to textbooks, stationery and uniforms – essential items for classroom participation.

Working in tandem with the District Disaster Management Authority, local government bodies, School Management Committees and community stakeholders, ADRA India implemented a targeted three-month rehabilitation project from October 2025 through January 2026. The collaborative approach ensured that intervention efforts reached the most severely impacted educational institutions within a region where flooding had submerged over 324 villages, causing prolonged disruption to essential services including education.

The restoration initiative prioritised the repair and upgrade of water, sanitation and hygiene facilities across 12 government schools, directly benefiting approximately 697 children through renewed access to safe and functional toilets. Beyond infrastructure rehabilitation, the project distributed comprehensive education kits to 585 particularly vulnerable students, including children from daily wage worker families, migrant households, women-led families and historically marginalised communities. This intervention alleviated the financial burden on families already strained by disaster losses while enabling students to resume their education promptly.

Sustainability remained central to the project's design, with School Management Committees receiving orientation on routine maintenance of rehabilitated facilities to ensure their long-term functionality. Infrastructure repairs incorporated enhanced durability measures specifically intended to withstand potential future flooding, thereby strengthening the resilience of educational facilities in this disaster-prone region.

Dr Aaditya Sharma, IAS, SDM Dera Baba Nanak, said, “Following the floods that affected Dera Baba Nanak Sub-Division, several government schools suffered damage to essential infrastructure, particularly Water, Sanitation and Hygiene (WaSH) facilities, resulting in disruption to the education of school-going children. The restored sanitation infrastructure has helped ensure a safe, hygienic and dignified learning environment for students, especially for girl students.”

Sudhir Kulkarni, Executive Director HR, Admin & CSR, Bridgestone India, said, “Bridgestone is committed towards Serving Society with Superior Quality. This inspires us to offer the best to the communities that we serve. Education is a critical pillar for communities, and this was most impacted by the floods. We have, in our humble way, contributed towards restoring some of the educational facilities in the Dera Baba Nanak block, thus safeguarding learning and well-being when vulnerable communities needed it the most.”

Imran Majid, Programmes Director, ADRA India, said, “In post-disaster settings like Dera Baba Nanak, children are among the most vulnerable. Restoring safe and functional WASH facilities in schools is not just about infrastructure, it is about protecting children’s health, dignity and right to learn. When sanitation and hygiene are compromised, the risks of illness increase and school dropouts become more likely, especially for girls. Through the School WASH project, we are ensuring that schools become safe, hygienic spaces again, enabling children to return, stay and thrive in their education.”

Comments (0)

ADD COMMENT