CUTTING EDGE: DR JÖRN SEEVERS OF KE FISCHER DISCUSSES THE FUTURE OF TYRE PRODUCTION

- By Sharad Matade

- April 23, 2024

In an interview with Dr Jörn Seevers, CEO of KE FISCHER, the world leader in cord cutting technology, we delve into the company’s strategic growth and its vision for the future. The discussion explores the significance of the recent acquisition of KONŠTRUKTA-TireTech (K-TT) and its impact on KE FISCHER’s position in the market. We also gain insights into the crucial role of cord cutting lines in tyre production, the challenges they address and the opportunities it presents. Seevers sheds light on how KE FISCHER navigates the evolving regulatory environment and outlines the company’s vision for the future of cord cutting lines, emphasising innovation, quality, and environmental sustainability.

How has the business developed after the acquisition of KONŠTRUKTA-TireTech?

The acquisition of KONŠTRUKTA-TireTech, s.r.o. (K-TT) in Slovakia by KE FISCHER marks a significant step towards strategic growth and expansion in the tyre manufacturing industry. KE FISCHER has outlined ambitious plans for leveraging the acquisition to explore organic and inorganic growth opportunities. The collaboration aims to enhance the engineering and production capabilities. Additionally, KE FISCHER is focusing on expanding its service business model, which includes remote maintenance services for global customers.

The acquisition is expected to result in an even broader product range and customer base, combining KE FISCHER’s existing expertise in cutting and splicing technology with K-TT’s high-performance extrusion machinery. We expect this strategic move will foster accelerated growth, enhance customer relations and consolidate its presence in both segments of the tyre manufacturing industry.

In a strategic move to bolster its position within the tyre manufacturing sector, KE FISCHER is expanding its machinery portfolio and developing innovative equipment through a collaborative partnership with K-TT. This synergy will unlock new opportunities for both companies, fostering technological advancements, service offerings and overall industry growth.

Can you elaborate on the importance of cord cutting lines in producing various types of tyres?

Cord cutting lines play a critical role in producing various types of tyres, impacting quality and performance characteristics. The lines are so-called bottle-neck machinery and are essential for keeping the production of the whole tyre plant running.

Cord cutting lines are designed to cut the fabric or steel cord materials that reinforce tyres with high precision. This precision is essential for the tyre’s structural integrity and quality. Accurate cuts lead to efficient material usage, reducing waste and improving the overall cost-effectiveness of the production process.

How rubberised cord material is cut and laid out in the tyre can significantly affect its performance characteristics, including strength, flexibility and wear resistance. For example, the angle at which the rubberised cord material is cut and positioned can influence the tyre’s handling, stability and traction. Precise cord cutting technology optimises these angles, enhancing the tyre’s performance for its intended use, whether for passenger vehicles, trucks, bicycles, agricultural vehicles or performance racing vehicles.

Modern cord cutting lines are often integrated with quality control technologies, such as cameras and sensors, to detect material flaws or errors in the cutting process. This integration helps ensure that only materials that meet strict quality standards are used in tyre production, leading to tyres of superior quality.

Different types of tyres, such as radial versus bias tyres, require different cord arrangements and materials. Radial tyres, for instance, have cords that run perpendicular to the direction of travel, offering improved handling and wear characteristics. Bias tyres have cords that run at an angle to the direction of travel, providing a comfortable ride at lower speeds. Cord cutting lines must be versatile enough to handle different materials such as fabric, steel and others, and cutting specifications to produce a wide range of tyre types.

Automated cord cutting lines in tyre manufacturing enhance production efficiency and consistency and increase machine availability. Automation allows for the rapid processing of materials with minimal human intervention, reducing the likelihood of errors and increasing production speed. This efficiency is critical in meeting the high demand for tyres across various sectors, including automotive, aviation and industrial machinery.

Efficient cord cutting lines also contribute to sustainability efforts in tyre manufacturing. Manufacturers can minimise their environmental footprint by optimising material usage and reducing waste. Additionally, precise cutting reduces the need for excess raw materials, contributing to more sustainable production practices.

In summary, cord cutting lines are essential in tyre manufacturing, influencing everything from the efficient use of materials and production costs to the final product’s performance, quality and environmental impact. These lines’ precision, automation and versatility enable manufacturers to produce tyres that meet diverse requirements, ensuring safety, reliability and performance.

Thanks to operating in a niche, KE FISCHER is in constant contact with tyre manufacturers, and thus, it can be aware quickly of any possible challenge.

Each type of tyre requires a specific material, e.g. fragile material for bicycle tyres, or extremely thick material for OTR tyres.

What specific challenges in the tyre production industry led KE FISCHER to specialise in cord cutting lines?

The first cutting line for the tyre industry was built in the 1970s when a German-based tyre manufacturer asked KE FISCHER to investigate this field because of KE FISCHER’s immense experience and excellent know-how in cutting sheet metal products.

After this first line was successfully put into production, the door was now open for this new field of activity. KE FISCHER gained more expertise in producing cord cutting lines for the tyre production industry, which is a response to several specific challenges and needs within the sector. Integrating cord cutting seamlessly into the tyre manufacturing process improves efficiency and reduces production times. Specialised lines can be designed to fit into existing production lines, enhancing workflow and productivity.

The tyre industry constantly evolves with new materials, designs and specifications. Specialising in cord cutting lines allows KE FISCHER to stay at the forefront of technological advancements, offering solutions that meet the latest industry standards and requirements. Tyre manufacturers require customised solutions to meet specific production needs. A company specialising in cord cutting lines can offer more flexible and tailored solutions than a generalist machinery supplier, addressing unique challenges tyre producers face. The industry faces strict safety and environmental regulations. Specialised cord cutting lines can help manufacturers comply with these regulations by ensuring precise cuts that reduce waste and incorporating features that minimise ecological impact.

KE FISCHER’s focus on developing specialised cord cutting lines reflects a strategic response to these challenges, positioning the company as a critical partner for tyre manufacturers seeking to improve their production processes, enhance product quality and achieve greater operational efficiency.

Where does the company find more opportunities among the applications – from bicycles and cars to off-the-road and aeroplanes?

KE FISCHER specialises in providing cutting lines for the tyre industry, focusing on various applications from two-wheel vehicles, light vehicles and trucks to OTR tyre manufacturers. The company is a world leader in developing and manufacturing steel and textile cord cutting lines used for all kinds of tyres. This indicates that KE FISCHER is actively involved in supplying equipment essential for the production of tyres across a broad spectrum of vehicle types, including bicycles and cars.

The opportunities for KE FISCHER, among its various applications, depend on the demand for tyres in each sector. Given the company’s focus on providing cutting lines for tyre manufacturers, sectors with high growth in tyre demand would present more opportunities. The automotive and OTR sectors are traditionally large consumers of tyres, driven by both consumer demand and industrial applications. The bicycle sector has also grown, especially with the rise in eco-friendly transportation and urban cycling.

How does KE FISCHER navigate and adapt to changes in the tyre production industry’s regulatory environment?

KE FISCHER adapts to changes in the regulatory environment through several key strategies. KE FISCHER focuses on continuous research and development to ensure its machinery meets the latest environmental and safety standards, following EU safety regulations for all lines delivered. This includes investing in new technologies that reduce emissions, increase energy efficiency and incorporate safer, more sustainable materials.

By working closely with tyre manufacturers, KE FISCHER can understand the specific challenges and requirements these companies face due to regulatory changes. This collaboration helps in designing and modifying equipment that aids manufacturers in meeting new standards. The company’s global footprint allows it to gain insights into trends. This international perspective is of great importance for anticipating future shifts and adapting its offerings accordingly.

These strategies enable KE FISCHER not only to navigate but also to thrive amidst the evolving regulatory landscape of the tyre production industry.

What is KE FISCHER’s vision for the future of cord cutting lines, and how does it plan to stay ahead in the market?

KE FISCHER envisions its future in the cord cutting lines market with a strong focus on customer needs, innovation, quality and environmental sustainability. The company aims to maintain its position as a global leader by continuing to develop cutting-edge machinery that meets the evolving needs of the tyre industry. With a rich history of success and a commitment to research and development, KE FISCHER emphasises the importance of adapting to the continuous improvements in tyre material mixes, which requires staying up-to-date on material behaviour and adjusting cutting lines accordingly. This adaptability ensures the highest quality and efficiency of its products.

KE FISCHER’s strategic plan includes a commitment to development and design, aiming to remain the market leader by continuously developing improved and future-oriented solutions for cord cutting lines. The company leverages its extensive experience and track record of over 900 lines installed globally to enhance its technological leadership and quality standards.

KE FISCHER’s cutting lines and K-TT extrusion lines are equipped with the latest innovative technologies from suppliers and include in-house developed Industry 4.0 solutions.

In summary, KE FISCHER’s vision for the future of cord cutting lines revolves around innovation, quality, sustainability and customer-centric solutions. By continuously improving its technology and services, KE FISCHER’s explicit goal is to stay ahead in the market and meet the dynamic needs of the tyre manufacturing industry.

Continental’s Mount Vernon Tyre Plant Earns ISCC PLUS Certification

- By TT News

- December 10, 2025

Continental’s Mount Vernon, Illinois, tyre facility has achieved a significant corporate milestone by becoming the company’s first US location to attain ISCC PLUS certification. This globally acknowledged standard verifies the transparent tracing and documented use of recycled and renewable feedstocks in manufacturing. The achievement aligns with Continental’s broader goal of incorporating at least 40 percent sustainable materials in its tyres by 2030, reinforcing its dedication to sustainable mobility in the American market.

This certification follows similar accomplishments across Continental’s European tyre plants and its facility in Hefei, China, underscoring a worldwide strategy. The Mount Vernon site itself has a long manufacturing history, having operated for over five decades. Originally opened in 1974 and acquired by Continental in 1987, the plant now produces tyres for passenger vehicles, light trucks and commercial vehicles. With an annual output of roughly 11.4 million tyres, the 320,000-square-metre location employs nearly 3,900 people.

Central to this material transition is the mass balance approach, a chain-of-custody method that allows certified sustainable materials to be mixed with conventional ones in production while being tracked through meticulous accounting. This system enables Continental to precisely attribute specific quantities of alternative raw

Nik Pearce, Head of the Continental tyre plant in Mount Vernon, Illinois, said, “We are very pleased that our plant has received ISCC PLUS certification. This certification confirms our commitment to increasingly sustainable production processes and recognises the outstanding efforts of our entire team. Together, we are implementing Continental’s global sustainability strategy at the local level – transparently, responsibly and with a clear focus on the future.”

Jorge Almeida, Head of Sustainability, Continental Tires, said, “We rely on transparent and traceable supply chains. That’s a fundamental prerequisite for making our tyres increasingly sustainable. The certification of our largest US plant marks another important step in this direction. It enables us to integrate more sustainable materials into our product portfolio in every region where we operate.”

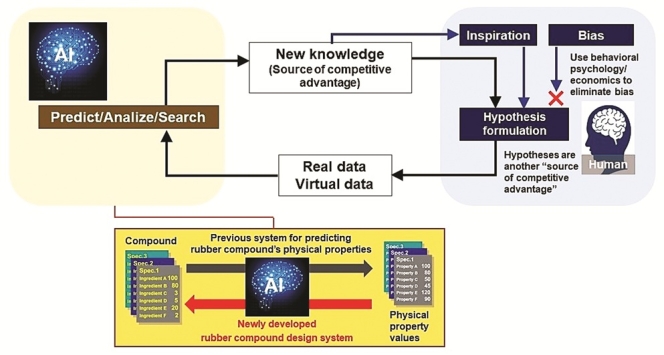

production defects in the final product and increase productivity with AI based scanning, inspection, real-time decision-making processes.

Digitalisation in the tyre industry is a gradual process that will improve performance, quality and profitability being on the way of real Industry 4.0 applications in tyre manufacturing. It continually opens up new opportunities to leverage data for better decision-making. Overall, digitalisation in tyre manufacturing is a powerful tool that unlocks the full potential of production. However, after implementation, continuous investment, as well as internal research and improvements, are required.

The tyre manufacturing industry is constantly evolving. Machines are becoming increasingly automated, more precise and data-driven. Recent advances based on the principles of Industry 4.0 include the aforementioned IoT, AI (artificial intelligence), robotics and sustainability.

Industry 4.0-driven digitalisation is based on the concept of the ‘digital twin’, meaning every machine is a data node. Data from every step (compound parameters, component dimensions, curing profiles) is collected for each tyre. This creates a virtual replica of the physical tyre, which is a ‘digital twin’ that enables complete traceability and data-driven process optimisation.

The role of humans is evolving from simple manual tasks to monitoring, diagnostics and data analysis. Robots, especially collaborative robots or cobots,

are taking over tasks such as final inspection and material handling. These revolutionary steps and concepts are having a major impact on manufacturing, optimising quality, performance, customer satisfaction and contributing to business success.

Modern mixing systems are increasingly replacing conventional tangential mixers. The intermeshing of the two rotors ensures more efficient and homogeneous mixing with better temperature control. This leads to higher mixing quality and consistency.

New mixing technologies, on the other hand, utilise ‘continuous mixing systems’, i.e. the continuous and simultaneous supply of all raw materials in precisely controlled quantities. The materials are continuously mixed in a series of specialised extruders and mixing units. At the end, a continuous stream of a perfectly homogeneous mixture emerges. This represents a revolution compared to conventional batch mixing. It improves energy efficiency, reduces the carbon footprint and enables unprecedented consistency and traceability.

Highly automated ‘multi-calender systems’ are equipped with multiple rollers that can simultaneously produce multiple layers (e.g. carcass ply, squeegee layer or inner liner) with extreme precision in thickness and width. Similar to extrusion lines with laser thickness control, these systems ensure 100 percent control and transmit data immediately to the extrusion head and calender roll clearances for automatic adjustment and maintenance of tolerances down to a fraction of a millimetre.

Thanks to the ‘multi-stage transfer’, the tyre casing is transferred between drums for the various production steps automatically and without human intervention, automatic cutting and splicing prevent deviations in quality. RFID technology integrated fully assures correct recipe and security in component application.

The robotic application and component preparation, such as with 6-axis robots, is now widely used for the fast and precise gripping and placement of complex components such as bead and apex assemblies.

Electric vulcanising presses are equipped with intelligent mould controls, whose integrated sensors monitor temperature and pressure in real time across multiple zones. The AI system dynamically adjusts the vulcanisation cycle (time, temperature, steam pressure) to ensure perfect curing of each tyre and compensate for any mould or material deviations.

Furthermore, predictive maintenance is now essential to avoid unplanned production downtime. Vibration, temperature and pressure sensors installed on manufacturing machines monitor all machine functions and alert when maintenance is required. High-precision servomotors, replacing pneumatic or hydraulic systems, work with servo-electric robots and are used in various production phases with submillimetre precision, reducing energy consumption and maintenance requirements.

The most visible technological advances in finishing and inspection lines today are fully automated with full sensitive cameras, AI-integrated and non-destructive testing (NDT) machines. Automated high-resolution X-ray machines scan each tyre to detect hidden defects such as trapped air, steel cord separation, or bead wire issues. Shearography and holography – being traditional but now equipped with intuitive, incredibly fast and precise modes – use lasers and intelligence to detect underlying defects or separations by measuring stress-induced deformations.

Uniformity and force variation measurement systems utilise AI algorithms to not only identify a tyre as ‘good’ or ‘bad’ but also diagnose the root cause of the deviation. Robotic trimming and polishing machines automatically locate and remove burrs (excess rubber) from the tyre using precise grinding tools – a traditionally manual and laborious task.

Of course, the future of tyre manufacturing, driven by advanced digitalisation, IoT and robotics, is rapidly evolving into a model for a smart, autonomous and sustainable industry, often referred to as ‘Tyre Industry 4.0’.

This transformation isn’t just about doing the same things faster; it will fundamentally change tyre design, production, sales and even performance. Tyre production facilities will become more autonomous, adaptable, efficient, predictive, personalised and, as expected, more sustainable.

Industry 4.0 and AI-powered digitalisation will accelerate sustainability. Precision manufacturing minimises material waste through the use of high-precision components. AI can easily manage energy consumption throughout the factory. IoT sensors monitor the overall condition of tyres, ensuring fast tyre changes, safety and performance.

This transformation will lead to safer, more efficient and more environmentally friendly tyres.

- BKT Tires

- Balkrishna Industries Ltd

- Sword of Honour 2025

- British Safety Council

- Health & Safety Management

BKT Awarded British Safety Council’s 2025 Sword of Honour For Safety Excellence

- By TT News

- December 08, 2025

Balkrishna Industries Ltd (BKT), a global leader in Off-Highway tyre manufacturing, has received the British Safety Council’s 2025 ‘Sword of Honour’ for exemplary workplace health and safety management. The honour was presented during a ceremony at London’s Drapers’ Hall.

BKT earned this distinction after its flagship Bhuj production facility in India attained a flawless Five-Star Audit Report, the highest possible rating within the Council’s audit framework. The award acknowledges the plant’s exceptional dedication, rigorous efforts and sustained commitment to managing occupational risks. BKT was among only 70 organisations worldwide to qualify for the 2025 Sword of Honour. As a recipient, the company has been presented with a custom-made stainless-steel ceremonial sword. This achievement underscores BKT’s ongoing organisational priority to foster and maintain industry-leading safety standards across its operations.

Peter McGettrick, Chairman of British Safety Council, said, “On behalf of the Board of Trustees and all staff of the British Safety Council, I would like to congratulate BKT on achieving the highest standards within its health and safety management. Achieving recognition of this kind involves full dedication and utmost professionalism. We are proud to support you in your achievements and are delighted that we can contribute to your ongoing success.”

Mike Robinson, Chief Executive of British Safety Council, said, “I would like to congratulate BKT and its staff on this award, in tribute to their commitment to keeping their workplace safe and healthy.”

Anil Kumar Sharma, Corporate Head of Quality Assurance and Sustainability, BKT, said, “The recognition of the British Safety Council rewards the great perseverance of BKT’s employees in putting in place a high-level and high-quality workplace for all, and I personally wish to congratulate all of them to promote the company’s highest standard in every operation.”

- United Nations Economic Commission for Europe

- UNECE

- Jean Rodriquez

- Working Party on Noise and Tyres

- GRBP

Global Tyre Standards

- By Gaurav Nandi

- December 08, 2025

In a discussion with Tyre Trends, Chief of the United Nations Economic Commission for Europe (UNECE) Information Unit Jean Rodriguez detailed how the Working Party on Noise and Tyres (GRBP) is driving international regulations on tyre safety, noise and sustainability. From pioneering micro-plastic emission measurement to strengthening wet-grip requirements and updating studded and retreaded tyre rules, Rodriguez emphasised UNECE’s role in shaping a harmonised global framework that balances consumer safety with environmental protection.

What is the role of the Working Party on Noise and Tyres (GRBP) within UNECE?

As one of the six subsidiary bodies of the World Forum for Harmonisation of Vehicle Regulations, hosted by UNECE, the Working Party on Noise and Tyres continues to spearhead globally harmonised standards through UN Regulation No. 117, covering tyre rolling resistance, noise, wet grip and, with recent developments, abrasion measures. These UN Regulations form the backbone of safety and environmental tyre specifications adopted by numerous countries and a substantial share of tyre producers globally.

What were the key regulatory changes between 2022 and 2025?

In early 2024, the Working Party adopted the first-ever methodology to measure particle emissions from tyres, critical for tracking micro-plastic emissions via two protocols including real-world 8,000 kilometres convoy tests and 5,000 kilometres rolling-drum lab tests. These are slated for integration into a new UN Regulation by September 2025 for passenger tyres, expanding into heavier vehicle categories (C2, C3) into 2026 and 2027.

Once in force, these regulations will contribute to significantly reducing micro-plastic pollution. In 2016, tyre abrasion was estimated to represent 78 percent of the 1.3 million metric tonnes of microplastics entering the ocean.

The UNECE methodology to measure particle emissions from tyres will become the reference methodology of the Euro 7 proposal of the European Union. Moreover, EU tyre regulation and labelling covering noise, wet grip, rolling resistance and environmental transparency build directly on UNECE’s standards.

How has UNECE addressed tyre safety at legal minimum tread depth?

GRBP introduced requirements ensuring that tyres at the legal minimum tread depth (1.6 millimetres) retain a minimum wet-grip level relative to new tyres. This is a shift towards safety and sustainability by permitting consumers to drive worn tyres safely, potentially reducing waste. It obliges manufacturers to design tread compounds and patterns that preserve wet performance over the tyre’s life, not just when new.

What regulations were introduced for studded tyres in 2022?

In September 2022, a new UN Regulation to cover performance requirements and marking of studded tyres entered into force to increase road safety by introducing harmonised snow grip requirements for studded tyres. It simplified the legislative situation in several countries that allowed the usage of studded tyres on public roads, introduced strict requirements and procedures for testing their snow grip and allowed consumers to benefit from more coherent winter tyre markings.

What additional areas has UNECE been working on to align safety and environmental goals?

By refining noise standards, updating testing protocols and promoting tyre lifecycle efficiency, UNECE is steadily shaping regulations to match environmental and safety objectives. This includes work on enhanced noise testing for tyres (UN Regulation No. 117) and motorcycles (UN Regulation No. 41) and vehicle alert systems (UN Regulation No. 138/51)

How does UNECE ensure global relevance, transparency and participation in its work?

All this work in setting technical specifications testifies to UNECE’s high relevance in providing a global harmonisation framework. Its expanding scope, especially in environmental dimensions such as micro-plastic emissions, is helping it maintain policy leadership and normative force, shaping tyre safety, noise and environmental performance worldwide.

A very important aspect of UNECE work is that it prevents fragmentation of the tyre regulatory landscape. GRBP is open to governmental experts from any member country of the United Nations and to any regional economic integration organisation set up by member countries of the United Nations including experts of governmental organisations and non-governmental organisations (NGOs).

UNECE provides secretarial support to WP.29 and its working parties, facilitating negotiations between contracting parties to the 1958, 1997 and 1998 agreements. More than 100 experts participate in the sessions of GRBP and all documents considered by GRBP are available in the public domain.

What are UNECE’s priorities going forward to support safety and the circular economy?

Leveraging its technical authority and norm-setting capacities, UNECE is uniquely positioned to foster a globally harmonised tyre labelling framework that covers rolling resistance, wet grip and, for the first time, tyre abrasion. This framework promotes consistency, environmental protection, consumer transparency and ultimately supports worldwide regulatory alignment.

At its session in September 2025, GRBP will consider the proposal for a new UN Regulation on the uniform provisions concerning the approval of tyres with regard to abrasion performance.

UNECE is also updating UN Regulations no. 108 (passenger car/towed vehicle Retreaded tyres), 109 (commercial vehicle retreaded tyres) and 172 (snow performance of retreaded tyres) to ensure retreaded tyres meet the same safety standards as new tyres, even in challenging winter conditions but in a way that makes regulatory processes smoother and more conducive to circular economy practices.

Comments (0)

ADD COMMENT