- Mercedes-Benz

- Mercedes-Benz India

- Chakan

- Maharashtra Pollution Control Board

- MPCB

- Siddhesh Kadam

- pollution

- violation

VIPO: Taking on new challenges

- By 0

- December 21, 2021

Utilising automation and digitalisation - known as digitisation in tyre manufacturing, presents a new perspective on all activities and tasks. Computer-aided systems make it possible to shorten continuous development and production times, increase time and performance usage of lines, and increase product quality while reducing the time needed for changing settings and to maintain the fleet.

In the past 20 years, VIPO a.s. has established itself as a leading manufacturer of automatic bead winding production lines. Based on the requirements of its customers and taking into account the trends in the tyre industry, in addition to continuously improving the existing lines, in 2014 VIPO a.s. started to invest in the development and acquisition of services-oriented services aimed at increasing production efficiency, in particular by reducing the time of line settings and maintenance, improving production quality and maintaining best practice directly in the factories and all of this in the most comprehensible form suitable for newly recruited workers as well.

In the past 20 years, VIPO a.s. has established itself as a leading manufacturer of automatic bead winding production lines. Based on the requirements of its customers and taking into account the trends in the tyre industry, in addition to continuously improving the existing lines, in 2014 VIPO a.s. started to invest in the development and acquisition of services-oriented services aimed at increasing production efficiency, in particular by reducing the time of line settings and maintenance, improving production quality and maintaining best practice directly in the factories and all of this in the most comprehensible form suitable for newly recruited workers as well.

In the area of digital competence, VIPO a.s. focuses mainly on 3 interconnected areas:

1) Advanced Condition Monitoring (ACM) - advanced condition monitoring including predictive maintenance (Regression Analysis and Neural Networks);

2) Rapid Action Supporting System (RASS) - enabling rapid problem localization and immediate search for the necessary methodology and documentation using 3D scans, including the development and preservation of Best Practice;

3) Staff training - using multi-view instructional videos, respectively 3D virtual trainings and optimization principles of Quick Changeover (SMED), Poka-Yoke and ergonomic and safety principles.

Advanced Condition Monitoring

Shifting from reactive and preventive maintenance to predictive maintenance that allows all tasks to be performed at exactly the optimum time, thus reducing downtime and reducing scrap, is not possible without advanced condition monitoring and the appropriate analytical part of the necessary amount of data. In this area, VIPO uses its own specialists in statistics and neural networks, long-term know-how in the field of mechanical design and rubber chemistry. Data security in the process of data acquisition, processing and presentation is a matter of course. VIPO never stores tyre production and technology data without the consent of a particular tyre manufacturer. Data processing is possible on the manufacturer's servers, respectively in the cloud (according to customer preference).

Rapid Action Supporting System

RASS is a system using 3D Scan, respectively 360-degree panoramas of production technology for easier and faster orientation in space (especially for less-experienced or new workers). This interface is linked to live data on production parameters as well as on the current need for intervention (whether changes in settings or equipment maintenance). At the same time, the operator / maintenance staff makes use of all the necessary documentation (such as technology regulations, machine documentation and electrical documentation) quickly available to deal with the situation at a specific point of the technology. Thus, the system does not burden the workers in a time-consuming situation with too much information that may be generated when searching for the necessary documents and procedures. Using an intelligent search system in the Best Practice of the plant based on solving the same or similar problems, the worker can accomplish the tasks properly, on time and much faster than before RASS implementation.

RASS is a system using 3D Scan, respectively 360-degree panoramas of production technology for easier and faster orientation in space (especially for less-experienced or new workers). This interface is linked to live data on production parameters as well as on the current need for intervention (whether changes in settings or equipment maintenance). At the same time, the operator / maintenance staff makes use of all the necessary documentation (such as technology regulations, machine documentation and electrical documentation) quickly available to deal with the situation at a specific point of the technology. Thus, the system does not burden the workers in a time-consuming situation with too much information that may be generated when searching for the necessary documents and procedures. Using an intelligent search system in the Best Practice of the plant based on solving the same or similar problems, the worker can accomplish the tasks properly, on time and much faster than before RASS implementation.

Staff training

Based on our long-term experience with continuous improvement of our internal processes and products, VIPO a.s. has also integrated a staff training system - operations and maintenance - into the system. The training can be based on complex but also affordable instructional videos that are required by end-users, which, thanks to multi-vision technology, accurately and comprehensively depict the correct procedure for performing the desired task. The video tutorials emphasize all the key moments concerning the production technology itself, as well as ergonomics and occupational safety. “The cherry” on the trainings in the terms of production savings is the optimization of the processes, where, through a team of engineers, we are able to optimize processes in accordance with the principles of SMED (Single Minute Exchange of Die) and Poka-Yoke. For more demanding customer groups, we offer training in 3D virtual reality, which also enables automatic evaluation of the effectiveness of the training and the trained workers themselves.

Based on our long-term experience with continuous improvement of our internal processes and products, VIPO a.s. has also integrated a staff training system - operations and maintenance - into the system. The training can be based on complex but also affordable instructional videos that are required by end-users, which, thanks to multi-vision technology, accurately and comprehensively depict the correct procedure for performing the desired task. The video tutorials emphasize all the key moments concerning the production technology itself, as well as ergonomics and occupational safety. “The cherry” on the trainings in the terms of production savings is the optimization of the processes, where, through a team of engineers, we are able to optimize processes in accordance with the principles of SMED (Single Minute Exchange of Die) and Poka-Yoke. For more demanding customer groups, we offer training in 3D virtual reality, which also enables automatic evaluation of the effectiveness of the training and the trained workers themselves.

The main service that VIPO a.s. offers to its customers for supporting the challenges of 2020 is the complex system described above, the main effect of which is to save time when changing production technology settings, as well as performing service tasks. At the same time, the system contributes to reducing the number of scraps and also enables customers to develop and fully exploit their best know-how.

The main service that VIPO a.s. offers to its customers for supporting the challenges of 2020 is the complex system described above, the main effect of which is to save time when changing production technology settings, as well as performing service tasks. At the same time, the system contributes to reducing the number of scraps and also enables customers to develop and fully exploit their best know-how.

VIPO a.s. offers its know-how and services related to its own SMM (Smart Maintenance Module) software solution, but it is also able to integrate it into existing solutions of the world's leading IoT software manufacturers.

(For more information about Smart Maintenance Module and all services provided, please contact: Andrej Bencel, SMM Key Account Manager; abencel@vipo.sk; www.vipo.sk; www.smartmaintenance.sk

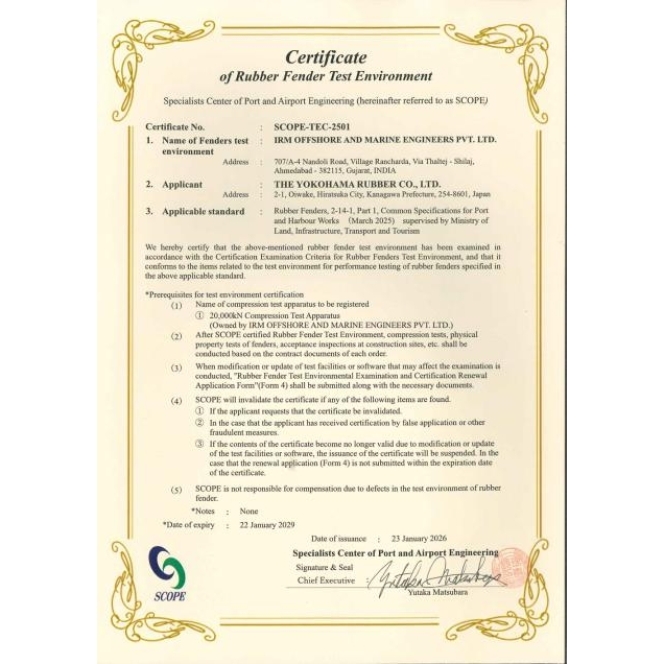

Yokohama Rubber Secures Certificate Of Rubber Fender Test Environment

- By TT News

- January 28, 2026

The Yokohama Rubber Co., Ltd. has successfully secured a Certificate of Rubber Fender Test Environment from Japan’s Specialists Center of Port and Airport Engineering (SCOPE), awarded on 23 January 2026. This certification follows a thorough assessment under SCOPE’s Rubber Fender Testing Environment Certification Program, which validates that the company’s testing facilities for marine rubber fenders operate with integrity and reliability. Specifically, the certification confirms that Yokohama Rubber employs a robust system designed to prevent data fraud, ensuring the trustworthiness of all test results for fenders it manufactures and sells.

These fenders serve as critical safety components, acting as cushioning buffers to protect vessel hulls from impact during harbour mooring and ship-to-ship transfers at sea. To promote safer and more secure maritime operations, SCOPE launched its certification initiative in April 2023, focusing on verifying the reliability of fender testing environments. The programme is aligned with technical guidelines from the World Association for Waterborne Transport Infrastructure (PIANC) and evaluates compliance across multiple SCOPE-defined criteria. These include adherence to static compression testing standards, the elimination of opportunities for data falsification, the integrity of statistical values in test data and the establishment of corporate systems that prevent tampering.

Yokohama Rubber’s expertise in this field dates to 1958, when it pioneered the world’s first pneumatic fender for offshore vessel berthing. Recently, the company has broadened its portfolio beyond high-performance pneumatic fenders to include solid fenders, which represent a principal segment of the fender market. This strategic expansion establishes Yokohama Rubber as a comprehensive fender manufacturer and reinforces its revenue foundation.

The achievement aligns with the company’s ongoing medium-term management plan, Yokohama Transformation 2026 (YX2026), which spans fiscal years 2024 to 2026. A key element of this strategy involves driving growth in the MB Segment by focusing resources on core domains such as hose and couplings along with industrial products. Within this framework, Yokohama Rubber aims to strengthen its product lineup and sustain strong market shares for marine products, including fenders, to secure steady profit growth in the industrial products business.

Bridgestone India Taps Punjabi Star Parmish Verma For Regional Growth Push

- By TT News

- January 27, 2026

In a strategic move to strengthen its connection with vital regional audiences, Bridgestone India has partnered with multifaceted Punjabi star Parmish Verma. This collaboration is designed to resonate deeply in North India, a crucial and rapidly expanding market fuelled by increasing vehicle ownership and a youthful demographic. Verma, a prominent cultural figure and known automobile enthusiast, aligns naturally with the brand’s emphasis on safety, reliability and performance. His authentic passion for vehicles and responsible driving complements Bridgestone’s identity as a leading mobility solutions provider.

Central to this alliance is the co-creation of engaging, music-led narratives and digital content for Bridgestone’s campaigns, leveraging Verma’s artistic talents and significant social influence. This approach recognises the powerful role of popular culture in shaping brand preferences within the region. The partnership also advances the company’s broader regional engagement goals, aiming to build deeper trust with consumers nationwide. Furthermore, it embodies the ‘Emotion’ principle of Bridgestone’s corporate commitment, which seeks to inspire excitement and deliver joy through mobility. By uniting with a figure of Verma’s reach and genuine interest, Bridgestone India fosters a more dynamic and culturally relevant dialogue with its audience.

Rajiv Sharma, Executive Director – Sales & Marketing, Bridgestone India, said, “North India is a strategically important market for us. Parmish Verma’s credibility and deep connection with audiences make him an ideal partner to represent Bridgestone. This collaboration enables us to engage meaningfully with young consumers who seek fresh, inspiring and relatable brand experiences.”

Verma said, “Bridgestone is a brand people trust for safety and performance. I’m proud to be associated with an organisation that values quality and puts customers first. I look forward to connecting with audiences in a new and meaningful way through this partnership.”

Bridgestone Americas Appoints Michele Herlein As New Chief People Officer

- By TT News

- January 24, 2026

Bridgestone Americas has appointed Michele Herlein as its new Chief People Officer. In this role, she will oversee all human resources operations across the Americas, Europe, Middle East and Africa. Her primary focus will be advancing the company's Culture 2.0 initiative, which aims to enhance teammate empowerment, collaboration and accountability.

Herlein rejoins Bridgestone with over two decades of executive leadership expertise. Her background includes previous positions within Bridgestone Americas and Bandag, Inc., centred on culture, leadership development and succession planning. Most recently, she was the Founder and CEO of CultureMax and previously served as the Chief Administrative and Human Resource Officer at Barge Design Solutions. She is also a published authority on creating high-performance organisational cultures. Beyond her corporate work, Herlein is a co-founder of Impact100 Nashville, a philanthropic women’s collective that has awarded more than USD 1.2 million in grants to area nonprofits.

Scott Damon, Bridgestone West CEO and Group President of Bridgestone Americas, said, “I am excited to welcome her back to Bridgestone, recognising the perspective and presence she will add to our West leadership team, the HR function and the broader organisation.”

- Alliance Tyres

- Yokohama-ATG

- Agri Star II Row Crop

- LAMMA UK 2026

- Agricultural Tyres

- Off-Highway Tyres

Alliance Displays Agri Star II Row Crop Tyre At LAMMA UK 2026

- By TT News

- January 24, 2026

Alliance, a prominent global tyre brand under Yokohama-ATG, introduced its new Agri Star II Row Crop tyre to the UK agricultural sector during the recent LAMMA UK 2026 event. This launch marked the product's UK debut following its initial presentation at Agritechnica 2025. The tyre is specifically engineered for row crop tractors and specialist machinery, including self-propelled and trailed sprayers, operating in crops such as cereals, maize and oilseed rape.

Central to the tyre's design is Alliance's Stratified Layer Technology (SLT), which incorporates two distinct rubber layers within each lug to maintain reliable traction and stability even as the tyre wears. This approach is part of a design focused on mitigating soil compaction through a wider tread that improves load distribution, thereby helping to protect soil structure and preserve crop yields.

To address the evolving demands of modern farming, the tyre is built for high-speed road travel, boasting an E-speed rating that allows for operational speeds up to 70 kmph. This capability accommodates the increasing distances machinery must cover between fields. Simultaneously, the tyre is engineered to provide effective low-pressure performance during actual field work. It brings VF technology to this segment, a critical development as agricultural equipment continues to grow in both weight and the frequency of road use.

The construction emphasises durability, incorporating features like a stubble guard and advanced, wear-resistant compounds to ensure a long service life under challenging conditions. Available in rim sizes ranging from 24 to 54 inches, the Agri Star II Row Crop is designed for compatibility with a broad spectrum of contemporary farm machinery. This new model extends the proven platform of the Agri Star II series, of which over one million units have been sold globally, delivering its established technological benefits into the specialised realm of row crop agriculture.

Comments (0)

ADD COMMENT