Nynas Powers Croatia's First Green Transformer With NYTRO BIO 300X Renewable Insulating Fluid

- By TT News

- November 25, 2025

Nynas has played a pivotal role in a landmark achievement for Croatia's energy sector by supplying its advanced NYTRO BIO 300X insulating liquid. This fully renewable fluid has been used for the first time in the Croatian market to fill a 630 kVA distribution transformer. The unit, manufactured by KONČAR – Distribution & Special Transformers, was recently installed in Zagreb for HEP ODS, the national Distribution System Operator.

This collaboration marks the inaugural deployment of a ‘Green Transformer’ in Croatia, representing a significant advancement for the country's distribution network. The project underscores a unified drive towards greater sustainability and a reduced environmental footprint for critical power infrastructure. For Nynas, this milestone highlights the practical application and reliability of its bio-based product portfolio.

NYTRO BIO 300X is engineered to provide a drop-in solution that combines high oxidation stability and superior cooling performance, allowing operators to enhance their ecological standards without compromising on operational reliability or transformer longevity. The successful installation stands as a testament to how industry partnerships are actively accelerating the transition to a more sustainable energy future.

Ivanka Radić, responsible for transformer oils at KONČAR - D&ST, said, “The thermal and dielectric tests on the transformer filled with NYTRO BIO 300X were successfully completed, and the unit is now fully operational. As expected, all test results were within the required limits, confirming the reliability and stability of this innovative fluid.”

Daniele Frustagli, General Manager Italy & the Balkans at Nynas, said, “We are very proud to have been entrusted with this project by KONČAR - D&ST and HEP ODS Zagreb, allowing us to showcase to them and the entire electrical industry the advantages of this fully renewable, bio-based hydrocarbon liquid. In addition to meeting and exceeding the IEC 60296 ed. 5 (2020) specification, the product is readily biodegradable, fully bio-based and has ultra-low viscosity.”

Vanja Burul, President of the Management Board at KONČAR - D&ST, said, “This project reflects our ongoing efforts to explore more sustainable insulating fluids. We see great potential for further use of NYTRO BIO 300X in future applications.”

Wacker Secures Top Score In CDP 2025 Annual Sustainability Ratings

- By TT News

- January 12, 2026

WACKER has earned a distinguished ‘A’ rating in the 2025 CDP sustainability assessment for its climate protection management. This is Wacker’s third time in a row on the A list by the global environmental non-profit organisation. Beyond the climate category, WACKER maintained its strong standing in water security, again achieving an A- leadership rating. In the forests category, the company secured a B management-level score. These consistent results highlight WACKER’s ongoing commitment to holistic environmental responsibility and transparent reporting across all key sustainability areas.

The CDP, a globally respected non-profit formerly known as the Carbon Disclosure Project, conducts the world’s premier environmental disclosure system. It annually evaluates thousands of organisations on behalf of investors, using a detailed questionnaire that spans climate change, water security and forests. Scores follow an A-to-F scale, with an A denoting exemplary performance and disclosure.

Among over 22,100 companies evaluated worldwide, WACKER’s top climate score places it in the premier tier. According to CDP, such a rating reflects comprehensive, high-quality data disclosure and robust transformation strategies.

Peter Gigler, Head of ESG at WACKER, said, “We have our sustainability performance independently audited by CDP every year, so we’re very pleased that we were able to maintain our top rating for the third time in a row.”

Midas, Asia’s largest manufacturer of tyre retreading materials, has launched O-rings designed for off-the-road (OTR) tyres, aimed at delivering reliable sealing performance in demanding operating conditions.

The O-rings are manufactured using high-quality natural rubber and are formulated to improve physical properties and ensure dimensional stability. According to the company, the product has been tested over many years in harsh environments and is intended to provide consistent, trouble-free performance in OTR tyre applications.

Midas said only REACH-compliant raw materials are used in the manufacture of the O-rings, underscoring its adherence to safety, quality and international regulatory standards.

Founded 56 years ago, Midas supplies tyre retreading materials to customers in more than 60 countries. The company said the launch reflects its continued focus on developing performance-oriented solutions for the global tyre and retreading industry.

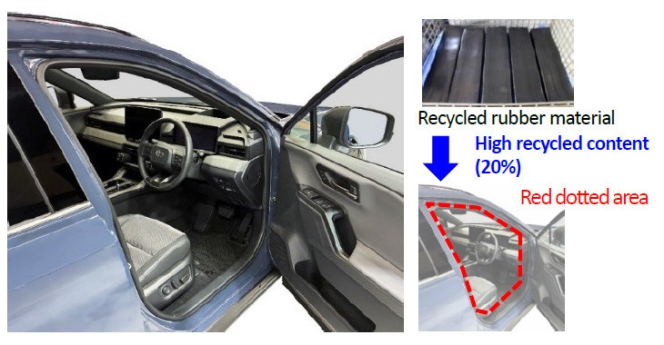

Toyoda Gosei Launches Automotive Parts With 20% Recycled Rubber

- By TT News

- January 08, 2026

Toyoda Gosei has successfully commercialised automotive weatherstrips using recycled rubber, starting with the new Toyota RAV4. This marks a significant breakthrough in a field where rubber has historically been difficult to reuse, often ending up incinerated instead of truly recycled. Unlike steel or plastic, rubber recycling requires devulcanisation, a complex process that traditionally weakens the material and leaves behind unpleasant odours.

Through dedicated refinement of its proprietary devulcanisation technology, the company has overcome these longstanding quality hurdles. The advancements have dramatically increased the usable proportion of recycled material in automotive parts from under five percent to 20 percent, an achievement honoured by a Toyota Motor Project Award.

Looking ahead, Toyoda Gosei aims to extend this technology beyond synthetic rubber to include natural rubber, which is used in far greater volumes. The broader corporate ambition is to collaborate with automakers and partners to establish a full circular system. This system would collect and regenerate rubber from end-of-life vehicles, positioning the company as an industry leader in enabling both decarbonisation and sustainable resource circulation.

Michelin Reinforces Polymer Composite Solutions Business With Two Acquisition Projects

- By TT News

- January 05, 2026

Pursuing its strategic goals for 2030, Michelin is actively extending its technological leadership into adjacent, high-value sectors. This expansion is being accelerated through two key acquisitions announced in recent months: Cooley Group and Tex Tech Industries. Both US-based companies are leaders in advanced materials, specialising in high-performance fabrics and coatings, and align strongly with Michelin’s own focus on innovation and quality while bringing complementary geographic and technical strengths.

Cooley Group, marking its centennial in 2026, excels in creating engineered polymer-coated fabrics. Its fully integrated production enables custom solutions for critical applications in healthcare, industrial containment and waterproofing. Similarly, Tex Tech Industries, with over a century of operation, designs and manufactures specialised textiles for extreme demands, including thermal protection systems for aerospace, fire-blocking aircraft interiors and advanced composite materials.

These strategic moves significantly bolster Michelin’s existing position in coated fabrics, notably through its European brand Orca. By integrating Cooley and Tex Tech, Michelin anticipates accelerating its global market reach and increasing the revenue of its Polymer Composite Solutions division by approximately 20 percent, equating to roughly USD 280 million. Given the growing scale of this business, Michelin intends to establish it as a dedicated reporting segment starting in 2026.

The acquisitions, slated for completion in the first half of 2026 pending regulatory approvals, will be transacted in cash, with financial terms currently undisclosed.

Comments (0)

ADD COMMENT