Like its peers, the Sri Lankan rubber industry has been hard hit by the COVID 19. However, the pandemics will bring some opportunities to the sector, believes Ravi Dadlani, Chairman of the Sri Lanka Association of Manufacturers and Exporters of Rubber Products (SLAMERP), and MD of CEAT Kelani Holdings. “The demand for PPE is high and will be sustained in time to come until COVID 19 is no longer a pandemic. Especially gloves and other wearables made of rubber will be a good area for the Sri Lankan rubber industry to focus on,” says Dadlani an interview with Tyre Trends.

How do you see the impact of COVID 19 on Sri Lanka’s rubber industry?

Sri Lanka, like all exporting countries, have been largely impacted. The shutdown has caused a tremendous loss both in terms of production and the subsequent shut down of countries resulting in the cancellation of orders widely across the tyre industry. We are concerned that the impact fully on the industry is still to be realised. We will, once the supply chain and the related industries come back online, be able to quantify the extent of the impact. We are however positive that the Sri Lanka rubber industry is poised to benefit from the need arising from the COVID 19 impact. Especially the demand for PPE is high and will be sustained in time to come until COVID 19 is no longer a pandemic. Especially gloves and other wearables made of rubber will be a good area for the Sri Lankan rubber industry to focus on. Also, the government suspension of importing of tyres is poised to increase demand for domestic manufacturers of tyres at least in the short term, which will be a boost to the local rubber industry. Impact on the loss of exports and the timings of the opening of overseas markets would be critical at this point.

The rubber industry has always been the country’s one of the main sectors and exporters. Do you think that the industry currently is being explored to its fullest potential?

There is a lot of potential for rubber in Sri Lanka. The need to increase the production of rubber through productivity improvements and the need to extend the rubber growing acreage is critical at this time. We have leading manufacturers of international repute and strong local manufacturers catering to export markets both in the tyre and gloves segments.

The country also has the potential to enter new markets and customer segments with new products. There is more that needs to be done in terms of R&D and technological collaborations to enter high-value rubber-based product segments. With major global brands producing in Sri Lanka, we have a greater ability to increase trading activity and improve international sales as a regional hub for the industry.

What kind of support do you expect from the government and industry-related bodies for the long term?

Firstly, the rubber sector was the first to benefit from the priority given by the government initiative to commence operations. The sector benefited by the fast track approval to be classified as an essential sector. We expect the government to continue to have consistency when it comes to policy matters. We are also seeing a strong support base coming in terms of the Board of Investment and the Export Development Board for the rubber cluster. We need to fast track the planned policy-based approach of increasing rubber production in the country through the rubber master plan, with incentives if need be for plantations to spearhead this initiative. Also, research and development on rubber yield increase, all-weather rubber tapping techniques need to be introduced with governments thrust towards increasing rubber production.

There should also be incentives for exporters to invest in high-value rubber product manufacturing. We expect the government to educate the smallholders with international best practices to manage the rubber crop for better yield and output through RDD & RRI as key government institutions. The industry prefers to buy more local rubber, but there is a shortfall every year vs the demand. We also need to drive the public-private partnership research & development and must invest more in laboratory and testing facilities to provide certifications that are required for the export markets within Sri Lanka. The Government will also need to look at domestic supply chain inefficiencies which may hold back on the growth potential of the industry.

When we talk about tyres, how does the Sri Lankan tyre industry make its mark globally, especially in the solid tyre segment?

Absolutely it does. Sri Lanka is considered market leaders in certain categories of the solid tyre export segment. There are the numbers of global and local companies operating out of Sri Lanka holding a good foothold in the global solid tyre market. The global rubber industry is worth around USD 400 billion, out of which 65% is the tyre industry, given this, we have a market that we can increase our supply of both off road and on-road tyres, Sri Lanka has aggressively ventured into the global pneumatic agriculture, Off-road and industrial tyre segment which is estimated at USD 44b. We are confident that this position of strength will be maintained in the future, too in these segments.

What are the challenges for tyre and rubber goods, especially for small and medium enterprises?

Key is the availability of rubber at consistent prices at the right quantities throughout the year. Currently, the industry is hampered with weather-related shortfalls in production coupled with plantations moving away from rubber and more profitable ventures depleting the total output. We consume 140,000 MT, and the local production is at 75,000 MT. Addressing these two areas will result in a stable supply of rubber for industries. It is very important that SMEs adopt technology and increase productivity and production to cater to the demand for rubber.

END

Global Natural Rubber Market Tightens Amid Improved Demand, ANRPC Reports

- By TT News

- November 07, 2025

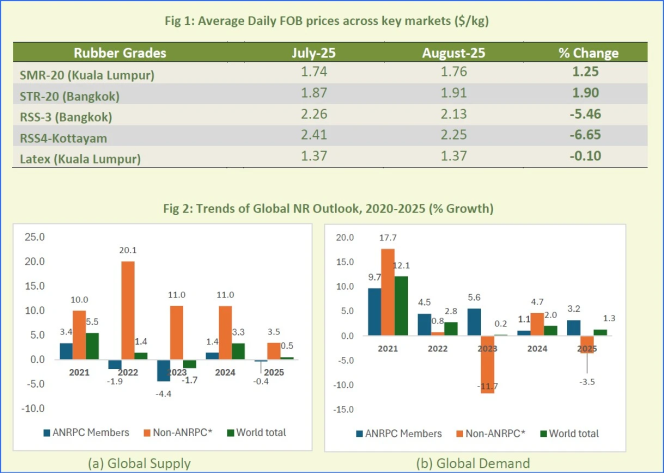

The global natural rubber (NR) market experienced fluctuating prices in August 2025 as supply constraints coincided with signs of improving demand, the Association of Natural Rubber Producing Countries (ANRPC) said in its latest Monthly NR Statistical Report.

The association noted that seasonal factors supported stronger consumption, particularly in China, where declining port inventories signalled healthier demand. However, heavy rainfall and labour shortages in key producing regions curtailed tapping activities, tightening supply conditions.

“Natural rubber prices experienced a fluctuating trend due to several factors, including constrained supply and improving demand,” ANRPC said. “Seasonal factors boosted consumption, particularly in China, where inventory reductions at major ports indicated improved demand. However, rainfall and labour shortages in producing regions limited tapping activities, tightening supply.”

According to updated data from member countries, global natural rubber production is projected to increase by 0.5 percent in 2025 compared with 2024, while demand is expected to grow by 1.3 percent over the same period.

The association said market sentiment had turned “increasingly optimistic” with stronger purchasing interest, driven by the traditional peak season for natural rubber, especially from the all-steel tyre and heavy-duty truck segments.

The ANRPC encouraged subscribers and stakeholders seeking more in-depth insights to refer to the full report or contact the ANRPC Secretariat for subscription details.

India Opens Anti-dumping Probe Into Halobutyl Rubber Imports From China, Singapore And US

- By Sharad Matade

- November 06, 2025

India has launched an anti-dumping investigation into imports of Halo-Isobutene-Isoprene Rubber (HIIR) from China, Singapore and the United States, following a complaint from Reliance Sibur Elastomers Private Limited, the Directorate General of Trade Remedies (DGTR) said in a notification.

The domestic producer alleged that the three countries were exporting the rubber to India at unfairly low prices, causing injury to the local industry. The company has sought the imposition of anti-dumping duties on the product, which is used in tyre inner liners, hoses, seals, tank linings, conveyor belts and protective clothing.

The DGTR said there was prima facie evidence that imports had risen “significantly” and were being sold below normal value, resulting in price depression and affecting the domestic manufacturer’s capacity utilisation and profitability. The authority noted that the dumping “is causing material injury to the domestic industry”.

The investigation will cover the period from July 2024 to June 2025, with an examination of injury trends dating back to April 2021.

HIIR, also known as halobutyl rubber, is classified under the broader synthetic rubber tariff category. Reliance Sibur Elastomers is currently the only producer of the material within India.

If the investigation confirms dumping and injury, the DGTR may recommend the imposition of duties to offset the impact and “remove the injury to the domestic industry”. Interested parties have 30 days to submit data and make their representations to the authority.

Global Carbon Black Market To Hit USD 44.8 Bln By 2034, Driven By Tyre And Autom Demand

- By TT News

- November 06, 2025

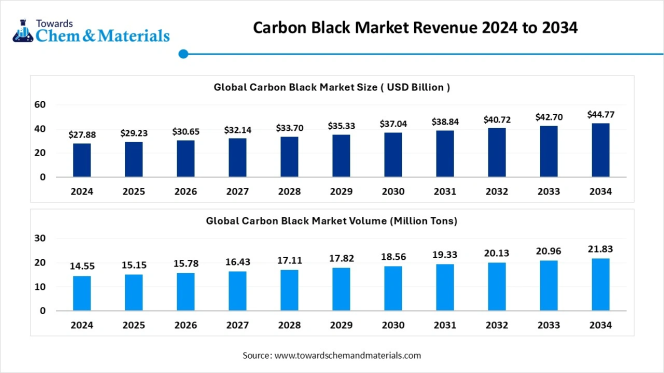

The global carbon black market is projected to grow from USD 27.88 billion in 2024 to USD 44.77 billion by 2034, expanding at a compound annual growth rate (CAGR) of 4.85 percent between 2025 and 2034, according to a new report by Towards Chemical and Materials, a research arm of Precedence Research.

The study estimates that the global market volume will rise from around 15.15 million tonnes in 2025 to 21.83 million tonnes by 2034, growing at a CAGR of 4.14 percent, driven primarily by increasing demand for tyres, automotive components and high-performance plastics.

Carbon black – a fine black powder made through the incomplete combustion of hydrocarbons – is a critical material used to reinforce rubber in tyre production and enhance strength, durability and UV resistance in plastics, coatings, and batteries.

Asia Pacific accounted for about 58 percent of global market share in 2024 and is expected to remain the largest and fastest-growing regional market, supported by expanding tyre and rubber manufacturing bases in China, India and Southeast Asia. The region’s carbon black market was valued at USD 16.95 billion in 2025 and is projected to reach USD 26 billion by 2034.

“The Asia Pacific region continues to lead both in production and consumption of carbon black, owing to its strong automotive, tyre and plastics industries,” the report noted, adding that China remains the world’s largest producer and consumer.

The furnace black segment dominated the market in 2024, accounting for about 60 percent of global industry share, due to its superior reinforcing properties in tyres and versatility in plastics and coatings. Meanwhile, the tyres and rubber products segment held a 55 percent share, reflecting the material’s indispensable role in the automotive sector.

Performance applications such as batteries, conductive polymers, and specialty coatings are emerging as key growth drivers. Demand for specialty carbon black and conductive grades is rising with the proliferation of electric vehicles, renewable energy systems, and electronics manufacturing.

Artificial intelligence (AI) is also shaping the carbon black industry, with automation and predictive analytics enhancing process efficiency, product consistency, and sustainability, the report said. AI-driven systems are enabling real-time monitoring and predictive maintenance in production plants, reducing waste and energy consumption.

Sustainability remains a key trend, with manufacturers investing in greener technologies, renewable feedstocks and recovered carbon black (rCB) from recycled tyres to meet circular economy goals. “Turning end-of-life tyres and rubber waste into recycled carbon black is opening new sustainable pathways for producers,” the study noted.

Among key players profiled in the report are Tokai Carbon Co., Ltd., Continental Carbon, Jiangsu C-Chem Co., Ltd., Himadri Speciality Chemical Ltd., Sid Richardson Carbon & Energy Company, Cancarb Limited, Philips Carbon Black Ltd., OCI Company Ltd., Columbian Chemicals Co. (Birla Carbon), Aditya Birla Group, and Raven SR, LLC.

Recent industry developments include PCBL Chemical Ltd.’s establishment of a wholly owned US subsidiary in Delaware in July 2025 to enhance supply chain localisation and strengthen its North American footprint, as well as the West Bengal government’s efforts to attract foreign investment in its carbon black industry to support the electric vehicle, tyre, and battery markets.

The report also forecasts rapid growth in North America, fuelled by clean manufacturing practices, sustainable process adoption and expansion in high-performance plastics and battery applications. Europe, meanwhile, is benefiting from stricter environmental regulations and the EU Green Deal, which are promoting eco-friendly and specialty grades.

The global carbon black market is expected to maintain steady long-term growth as manufacturers diversify into advanced applications and invest in sustainable production technologies to meet evolving industrial and environmental demands.

Kraton To Streamline Berre Polymer Operations Focus

- By TT News

- October 26, 2025

Kraton Corporation, a leading global producer of speciality polymers and high-value biobased products derived from pine chemicals, has revealed a new strategic initiative for its Berre, France facility. The plan involves streamlining its polymer operations to concentrate exclusively on manufacturing USBC products, which will result in the cessation of HSBC production at that site.

This move is designed to bolster Kraton's long-term competitiveness by optimising its manufacturing footprint in reaction to a global overcapacity for HSBC. The company has formally started an information and consultation process with the local Works Councils, with a final decision expected following this mandatory period. The company has reaffirmed its commitment to supplying HSBC from its broader global network and to leveraging its worldwide presence to continue adapting to market demands.

Prakash Kolluri, President, Kraton Polymers, said, “Our aim with this plan is to strengthen Kraton’s long-term competitive position by optimising our manufacturing footprint in response to changing market dynamics associated with global overcapacity of HSBC production capability. With this step, we are preparing Kraton for a sustainable future by securing Kraton’s position as the leading global HSBC producer. Kraton is fully committed to supporting our customers through this transition with supply of HSBC products produced within our unmatched global manufacturing network. We recognise the impact of these actions, and are committed to a safe, respectful and supportive transition. The health, safety and well-being of the employees remain our top priorities.”

Comments (0)

ADD COMMENT