Apollo Tyres Launches Vredestein Superpasso Pro High-Performance Bicycle Tyre

- By TT News

- April 29, 2025

Apollo Tyres Ltd has launched the Vredestein Superpasso Pro competition-ready road bicycle tyres. This is the first model in the company’s all-new range of high-performance bicycle tyres scheduled for launch throughout the coming year.

The Superpasso Pro was developed using Apollo Tyres' cutting-edge ‘TriComp’ technology in Europe, which combines several rubber compositions for the tread and sidewall to maximise rolling resistance, puncture prevention and traction in both wet and dry situations. While the tyre's shoulder is composed of a softer composition to improve cornering grip at all speeds, the centre of the tread features a tougher compound to reduce rolling resistance and to prevent penetration. The new Superpasso Pro achieves a 14 percent improvement in rolling resistance, a 23 percent increase in puncture resistance and an eight percent weight reduction when compared to its Vredestein predecessor.

For TLR tyres, the new ‘Active Control’ technology offers a novel design that substitutes a bridging gap for the conventional overlapping centre join. Because of this development, the tyre is lighter and quicker, offering better control, better feedback and unwavering comfort. In order to increase puncture resistance and provide consumers the assurance that they can go farther, the Vredestein tyre also has a reinforced breaker layer. As part of a business collaboration with Apollo Tyres, the Dutch professional cycling team BEAT Cycling Club has put the Superpasso Pro through a rigorous testing process. Three sizes of the new Vredestein tyre are available: 700x25C, 700x28C and 700x32C. Both tubeless-ready (TLR) and tube type choices are available.

Nic Knippers, Division Head – Vredestein Two Wheel Tyres, Apollo Tyres Ltd, said, “The Superpasso Pro represents a significant leap forward in tyre technology, offering cyclists a product that excels in both performance and durability. With its innovative design and advanced materials, it delivers unmatched speed, comfort and reliability for cyclists of all levels.”

Thijs Zonneveld, Sportive Director, BEAT Cycling Club, said, “As a team that consistently pushes the limits of performance, we’ve been thoroughly impressed by the Superpasso Pro. The advancements in rolling efficiency, grip and durability have been evident in both race-day conditions and intense training sessions, and we’re excited to continue using it in competition.”

- Comerio Ercole

- Tire Technology Expo 2026

- Tire Technology International Awards 2026

- Tire Manufacturing Innovation of the Year Award

Comerio Ercole Honoured With Top Innovation Award At Tire Technology Expo 2026

- By TT News

- March 07, 2026

Comerio Ercole has concluded a successful participation in the Tire Technology Expo 2026, a premier international event for the tyre sector held in Hannover, Germany. Over the three-day exhibition, the company’s stand drew considerable attention from a global audience of customers, partners and industry professionals. The event served as a vital hub for fostering technical dialogue and commercial relationships, leading to the acquisition of new orders and forward-looking discussions that resonated deeply within the international tyre manufacturing community.

A defining moment for the company at this year’s expo was its recognition at the Tire Technology International Awards for Innovation and Excellence 2026. Comerio Ercole was honoured with the ‘Tire Manufacturing Innovation of the Year’ award, an accolade that underscores its enduring commitment to technological advancement. This achievement was complemented by the company’s status as a finalist in three additional award categories, highlighting its pervasive leadership and innovative edge in calendering technology.

These accolades reinforce Comerio Ercole’s standing as a pivotal technology partner for the global tyre industry. The recognition affirms the company’s strategic focus on engineering increasingly sophisticated solutions to meet the evolving demands of the market and shape its future trajectory.

CEAT Drives Women’s Leadership And Inclusion Through Comprehensive Workplace Policies

- By TT News

- March 07, 2026

CEAT has introduced a comprehensive set of policies aimed at supporting the specific needs of its women employees and fostering their professional advancement. The organisation emphasises work-life balance as a means to enhance both personal well-being and workplace productivity, offering flexible remote work options in coordination with managers. A Wellness Leave policy allows women two days of monthly work-from-home or leave during menstruation without requiring justification, while shopfloor employees can access on-site Occupational Health Centres for shift changes or rest as necessary.

To cultivate leadership and career growth, CEAT has implemented targeted programmes such as Womentoring, the Women Accelerator Program and STARS, which focus on building digital, functional and leadership competencies. The EmpowHer Employee Resource Group further promotes inclusion and facilitates open dialogue within the organisation.

The company also provides extensive support for mothers, including 26 weeks of paid maternity leave, hospitalisation coverage and facilities such as crèches and lactation rooms across offices and plants. Returning mothers can benefit from flexible hours and a reduced four-hour workday until their child turns one, while shopfloor workers are assigned morning shifts during the first year after childbirth. A gender-neutral Child Caregiver Travel and Stay Policy ensures that caregiving responsibilities do not hinder career progression.

In manufacturing, CEAT has enhanced accessibility by introducing automated machinery, ergonomic fixtures and lift-assist devices. These changes have contributed to a 20 percent women workforce at the Chennai facility and 28 percent representation on the Nagpur shopfloor, which was the first in Maharashtra to introduce night shifts for women. Safe transport, women security personnel and ergonomic workplace design further support this inclusion. Collectively, these efforts reflect CEAT’s commitment to enabling women to lead and succeed in diverse roles.

ZC Rubber Exhibits Industrial And OTR Tyre Solutions At CONEXPO 2026

- By TT News

- March 07, 2026

ZC Rubber is showcasing an extensive selection of industrial and off-the-road tyre solutions at the CONEXPO-CON/AGG 2026 trade show, being held from 3 to 7 March 2026 in Las Vegas. Attendees can visit the company at booth #N11041 in the North Hall to explore products from its key brands, including WESTLAKE, TIANLI, ARISUN and YONGGU. These offerings are specifically engineered to withstand the rigorous demands of sectors such as construction, agriculture, forestry and material handling.

The display features a comprehensive range of products, such as radial OTR tyres, agricultural tyres, forest tyres, material handling tyres and rubber tracks. Each product is designed to deliver durability, superior traction and operational efficiency in challenging work environments. The exhibition provides an important platform for ZC Rubber to engage with industry professionals, highlight its technological advancements and demonstrate its commitment to supporting global construction and industrial sectors with reliable, high-performance solutions.

Visitors can explore the lineup and speak with the team to learn how these tyre solutions can enhance productivity across a wide variety of applications.

Benjamin Lou, Global OTR Director, ZC Rubber, said, “CONEXPO brings together the people and machines that keep the world building, and it’s a great place for us to connect with customers face-to-face. With brands like WESTLAKE, TIANLI, ARISUN and YONGGU under one roof, we’re able to offer a true one-stop tyre solution across construction, agriculture, forestry and material handling. Our goal is simple – help customers find the right tyre for every job, all in one place.”

Bridgestone Develops Industry-First TRWP Vehicle Collection Method For Trucks And Buses

- By TT News

- March 07, 2026

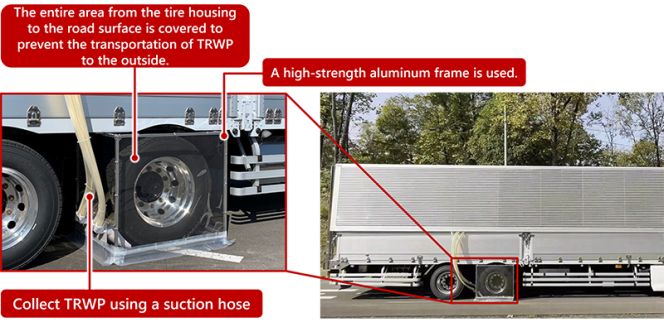

Bridgestone Corporation has announced a significant advancement in environmental research with the development of an industry-first vehicle collection method for tyre and road wear particles (TRWP) specifically from truck and bus tyres. This innovation is designed to enhance scientific understanding of how such particles may interact with the environment. Tyre and road wear particles are generated through the friction between a tyre’s tread and the road surface – a process essential for vehicle safety and comfort – and consist of a combination of worn tyre material and fragments of road pavement. The newly developed collection method for trucks and buses was also showcased at the Tire Technology Expo 2026, held from 3 to 5 March in Hannover, Germany.

The company had previously introduced a collection method for passenger car tyres in 2025 and has since been working to improve its efficiency. Applying insights gained from that earlier development, particularly regarding how particles are generated and dispersed, Bridgestone created a proprietary system tailored to the larger scale of truck and bus tyres. To ensure the accuracy of the collected samples, the company used a dedicated proving ground designed to replicate real-world driving conditions. Before each test, the track was meticulously cleaned to prevent contamination from pre-existing debris.

For the collection process, Bridgestone engineered suction devices and intake mechanisms compatible with larger tyres. A sturdy aluminium frame was used to construct the tyre cover, ensuring durability against strong winds during operation. Following controlled driving sessions, particles that remained both on the track surface and inside the tyre cover were gathered for analysis.

This effort is part of a broader commitment to investigate the physical and chemical characteristics of tyre wear particles and their potential environmental effects. Bridgestone participates in the Tire Industry Project (TIP) facilitated by the World Business Council for Sustainable Development and collaborates with external research organisations and corporate partners. With the ability to collect samples from both passenger vehicles and heavy-duty trucks and buses, the company aims to accelerate research, share findings widely and support efforts to reduce particle generation.

Alongside this research, Bridgestone is advancing several complementary initiatives. These include developing longer-lasting tyres with improved wear resistance, offering solutions that help customers lower total operating costs and working to minimise environmental impact throughout the product lifecycle.

Comments (0)

ADD COMMENT