Betting Big On R&D And Testing Capabilities

- By Sharad Matade

- October 13, 2021

JK Tyre is preparing for the future mobility demand, banking on its R&D and testing capabilities. The pioneer of radial tyre technology to green tyres in India, JK Tyre is in the process of launching new technologies from puncture-proof tyres to UUHP ( Ultra Ultra High Performance) and electric vehicles tyres for passenger cars and connected mobility solutions.

“If you look at the evolution of tyre technologies in India, today radialisation in the passenger car tyre segment has reached over 90 percent, while it is in the 50–55 percent range in the commercial tyres segment. In the next three to five years, the radialisation of commercial tyres will reach 65 to 70 percent. We will also see a fast transition from tube tyres to tubeless tyres in the country soon. New technologies such as smart tyres and puncture-proof tyres will pick up gradually segment-wise in India, catering to niche demand initially. As and when OEMs require these new technologies, our products will be readily available,” said Dr Rabindra Mukhopadhyay, director, R&D, JK Tyre & Industries,.

JK Tyre acquired Pune-based Treel Mobility. Today, JK Tyre is India’s only tyre company that indigenously manufactures Tyre Pressure Monitoring Systems (TPMS) based on TREEL sensor technology for OE and OE replacement markets. Its smart tyres provide live data on tyre temperature, tyre pressure, tyre positions, locations, distance travelled and expected tyre life through its algorithm, thus capturing the full health of the tyres.

The company is pushing its smart tyre solutions in the replacement market, especially for fleet companies. “It’s all about the value for money. If the customers think this product is value for money, they will pay for it,” said Dr Mukhopadhyay. The company’s smart tyres are available in PCR, 2-wheeler, LCV and truck categories.

The company is engaged in the manufacturing and marketing of automotive tyres, tubes and flaps. Today, the company has 12 state-of-the-art manufacturing facilities – three plants in Mysuru; three plants in Haridwar; one plant each in Banmore (MP), Kankroli (Rajasthan) and Chennai, and three plants in Mexico. These plants manufacture around 32 million tyres per annum.

JK Tyre’s products comprise truck & bus radial and bias, passenger car radials, two- and three-wheeler tyres, LCV & SCV bias and radial, off-highway tyres (OTR and Farm), as well as speciality tyres for military and defence, industrial and farm applications besides racing tyres.

Products in Pipeline

The company will soon introduce new products catering to the demand of new requirements, and one of them is a puncture-proof tyre for cars. The puncture-proof tyre has an inner coat of a special rubber compound developed by the company that seals and heals the tyre immediately. As per the company, its puncture-proof tyre can sustain up to 300 punctures. It also enhances durability and does not allow fuel efficiency to drop.

Bias tyres will also remain the focus of JK Tyre to maintain its leading position in the commercial tyres segment. According to Dr Mukhopadhyay, though India is aggressively moving towards the radialisation of commercial tyres, bias tyres will remain in demand for the next 15-20 years owing to the road conditions and the benefits it provides. “For short-haul and within-the-city transportation, bias tyres are still preferred. Globally, bias tyres still own around 10 percent market, and India is one of the leading exporters of bias tyres,” said Dr Mukhopadhyay.

Bias tyres will also remain the focus of JK Tyre to maintain its leading position in the commercial tyres segment. According to Dr Mukhopadhyay, though India is aggressively moving towards the radialisation of commercial tyres, bias tyres will remain in demand for the next 15-20 years owing to the road conditions and the benefits it provides. “For short-haul and within-the-city transportation, bias tyres are still preferred. Globally, bias tyres still own around 10 percent market, and India is one of the leading exporters of bias tyres,” said Dr Mukhopadhyay.

Tyres for EVs are expected to have lower rolling resistance, much lower tyre noise and high torque resistance with durability. JK Tyre has also developed new pattern series for electric scooters. For the scooter tyres, the company has a compound which has a 12 percent reduction in hysterias, leading to higher fuel saving and lower heat-related failures. JK Tyre is currently working with MG Motor to offer EV tyres on the passenger car tyre side. “We also have plans to offer electric passenger and light truck tyres,” added Dr Mukhopadhyay.

JK Tyre has also developed the second generation of EV tyres for passenger cars, which can up to 13 to 14 k per KVH.

Though niche, the high-performance bikes and car segment is gaining traction in India, and JK Tyre is also eyeing the same segment. For premium, high-end luxury cars, for domestic and export, JK Tyre has developed Levitas Ultra, an ultra-high-performance tyre. The Levitas Ultra offers the best in class ride and handling, braking, comfort and noise level. The company will also bring out ‘H’ rated tyres designed for high-speed motorcycles, which can reach 210 kmph, focusing on a lower aspect ratio. The company has tested and validated the Levitas Ultra tyre for India and Europe. The company claims the Levitas Ultra tyre’s performance is tuned at a level better than the global brands in overall handling, performance, control, wet grip and noise. “We are also working on non-pneumatic tyres, but it will take time to develop,” added Dr Mukhopadhay.

R&D and Testing Capabilities

R&D has always been an integrated focus of JK Tyres to bring new technologies. A few decades ago, almost all tyre companies in India collaborated with foreign tyre companies to get technologies. To reduce dependency on international companies, JK Tyre established India’s first independent elastomer and tyre research institute, Hari Shankar Singhania Elastomer & Tyre Research Institute (HASETRI), in 1991 at Kankroli, Rajasthan. Today, HASETRI is one of the leading research institutes in Asia in rubber and tyre technology. HASETRI works in material characterisation, product characterisation, simulation, environmental analysis, calibration, consultancy and training.

R&D has always been an integrated focus of JK Tyres to bring new technologies. A few decades ago, almost all tyre companies in India collaborated with foreign tyre companies to get technologies. To reduce dependency on international companies, JK Tyre established India’s first independent elastomer and tyre research institute, Hari Shankar Singhania Elastomer & Tyre Research Institute (HASETRI), in 1991 at Kankroli, Rajasthan. Today, HASETRI is one of the leading research institutes in Asia in rubber and tyre technology. HASETRI works in material characterisation, product characterisation, simulation, environmental analysis, calibration, consultancy and training.

In 2018, JK Tyre inaugurated its Global Technology Centre RPSCoE in Mysuru, bringing together the best in class facilities under one roof. The RPSCoE houses HASETRI and The JK Tyre Tech Centre. The company is ramping up its R&D and testing capabilities to meet future requirements. This year, the company has allocated a budget of INR 1.1 billion to procure equipment for tyre analysis. JK Tyre has already ordered the Flat-Trac CT Plus system, made by MTS, which is engineered to deliver highly accurate and repeatable measurements of tyre force and moment properties under steady-state and dynamic conditions. The machine, which costs over INR 500 million, has capabilities of steady-state force and moment measurement, dynamic force and moment measurement, sinusoidal radial deflection tests, simulation testing and effective rolling radius measurement. Another highlight of the centre is semi-anechoic chamber for noise, harshness and vibration measurement. JK Tyre was also the first tyre company in India to invest in a first-of-its-kind semi-anechoic chamber.

JK Tyre also has a centre of excellence at IIT Madras, a joint venture between the company and IIT Madras. Over the years, the company has developed many predictive technologies and other solutions at the centre. The IIT Madras centre has a virtual proving ground to have the actual performance for the tyres on a vehicle without having real tyres or vehicles. Various data for the vehicles and a tyre is fed into the software, and you can put data of any test track and drive the car with different speeds. The virtual proving ground helps the company generate various data to determine what kind of tyres is best suited for a particular vehicle.

JK Tyre also has a centre of excellence at IIT Madras, a joint venture between the company and IIT Madras. Over the years, the company has developed many predictive technologies and other solutions at the centre. The IIT Madras centre has a virtual proving ground to have the actual performance for the tyres on a vehicle without having real tyres or vehicles. Various data for the vehicles and a tyre is fed into the software, and you can put data of any test track and drive the car with different speeds. The virtual proving ground helps the company generate various data to determine what kind of tyres is best suited for a particular vehicle.

For enhancing its door testing capabilities, JK Tyre is also establishing its wet grip testing capability. The company has bought a skid trailer used for on-road tyre characterisations- force & moment, rolling resistance dry and wet grip. Currently, it is at NATRiP, Indore.

Recently, HASETRI received accreditation from the prestigious National Accreditation Board for Testing & Calibration Laboratories (NABL) for outdoor regulatory testing as per ISO/IEC 17025:2017. With this, HASETRI has become the first Scientific & Industrial Research Organisation (SIRO) recognised by DSIR, Government of India and an independent tyre testing and research institute in India to receive such accreditation from NABL.

Under the scope for outdoor testing, the accreditation includes testing for wet grip and coast-by noise for C1 (passenger) and C2 (light truck) category tyres as per ECE R117 method. The indoor tyre testing facilities for regulatory requirement like rolling resistance, endurance, dynamic growth etc. have already been accredited by NABL as per ISO/IEC 17025:2017.

Under the scope for outdoor testing, the accreditation includes testing for wet grip and coast-by noise for C1 (passenger) and C2 (light truck) category tyres as per ECE R117 method. The indoor tyre testing facilities for regulatory requirement like rolling resistance, endurance, dynamic growth etc. have already been accredited by NABL as per ISO/IEC 17025:2017.

JK tyre is exploring many possibilities on the material development front, one of which is mixing solid and liquid materials. “We are exploring possibilities of mixing natural rubber at the level of latex form with other solid materials. With this mixing process, we can save lots of energy consumption,” said Dr Mukhopadhyay. The company is working with different raw materials suppliers, especially synthetic rubber suppliers like SBR, to convert petrol-based materials to non-petrol based materials.

Reuse, retread and recycle are also focus of the company. Currently, the company is using three percent recycled rubber in its new products. In the future, it targets to have 10 percent recycled rubber in the new products in the next five years. “However, a greater challenge is to have virgin rubber properties in the recycled rubber,” added Dr Mukhopadhyay.

JK Tyre is also targetting to increase its retread tyre volume . As of now, it is retreading 300 tonnes of used tyres per day, aiming to take it to 500 tonnes per day. (TT)

ZC Rubber Exhibits Industrial And OTR Tyre Solutions At CONEXPO 2026

- By TT News

- March 07, 2026

ZC Rubber is showcasing an extensive selection of industrial and off-the-road tyre solutions at the CONEXPO-CON/AGG 2026 trade show, being held from 3 to 7 March 2026 in Las Vegas. Attendees can visit the company at booth #N11041 in the North Hall to explore products from its key brands, including WESTLAKE, TIANLI, ARISUN and YONGGU. These offerings are specifically engineered to withstand the rigorous demands of sectors such as construction, agriculture, forestry and material handling.

The display features a comprehensive range of products, such as radial OTR tyres, agricultural tyres, forest tyres, material handling tyres and rubber tracks. Each product is designed to deliver durability, superior traction and operational efficiency in challenging work environments. The exhibition provides an important platform for ZC Rubber to engage with industry professionals, highlight its technological advancements and demonstrate its commitment to supporting global construction and industrial sectors with reliable, high-performance solutions.

Visitors can explore the lineup and speak with the team to learn how these tyre solutions can enhance productivity across a wide variety of applications.

Benjamin Lou, Global OTR Director, ZC Rubber, said, “CONEXPO brings together the people and machines that keep the world building, and it’s a great place for us to connect with customers face-to-face. With brands like WESTLAKE, TIANLI, ARISUN and YONGGU under one roof, we’re able to offer a true one-stop tyre solution across construction, agriculture, forestry and material handling. Our goal is simple – help customers find the right tyre for every job, all in one place.”

Bridgestone Develops Industry-First TRWP Vehicle Collection Method For Trucks And Buses

- By TT News

- March 07, 2026

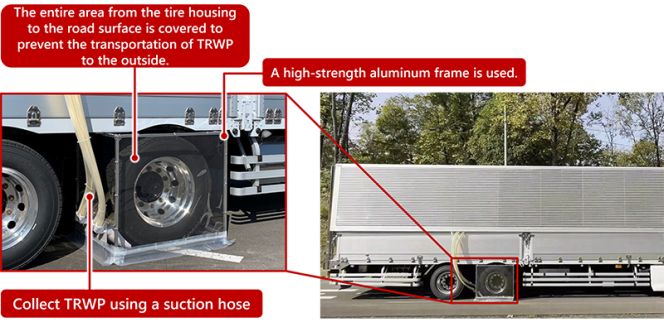

Bridgestone Corporation has announced a significant advancement in environmental research with the development of an industry-first vehicle collection method for tyre and road wear particles (TRWP) specifically from truck and bus tyres. This innovation is designed to enhance scientific understanding of how such particles may interact with the environment. Tyre and road wear particles are generated through the friction between a tyre’s tread and the road surface – a process essential for vehicle safety and comfort – and consist of a combination of worn tyre material and fragments of road pavement. The newly developed collection method for trucks and buses was also showcased at the Tire Technology Expo 2026, held from 3 to 5 March in Hannover, Germany.

The company had previously introduced a collection method for passenger car tyres in 2025 and has since been working to improve its efficiency. Applying insights gained from that earlier development, particularly regarding how particles are generated and dispersed, Bridgestone created a proprietary system tailored to the larger scale of truck and bus tyres. To ensure the accuracy of the collected samples, the company used a dedicated proving ground designed to replicate real-world driving conditions. Before each test, the track was meticulously cleaned to prevent contamination from pre-existing debris.

For the collection process, Bridgestone engineered suction devices and intake mechanisms compatible with larger tyres. A sturdy aluminium frame was used to construct the tyre cover, ensuring durability against strong winds during operation. Following controlled driving sessions, particles that remained both on the track surface and inside the tyre cover were gathered for analysis.

This effort is part of a broader commitment to investigate the physical and chemical characteristics of tyre wear particles and their potential environmental effects. Bridgestone participates in the Tire Industry Project (TIP) facilitated by the World Business Council for Sustainable Development and collaborates with external research organisations and corporate partners. With the ability to collect samples from both passenger vehicles and heavy-duty trucks and buses, the company aims to accelerate research, share findings widely and support efforts to reduce particle generation.

Alongside this research, Bridgestone is advancing several complementary initiatives. These include developing longer-lasting tyres with improved wear resistance, offering solutions that help customers lower total operating costs and working to minimise environmental impact throughout the product lifecycle.

UTAC Expands In China With New EV-Focused Proving Ground In Anhui

- By TT News

- March 07, 2026

UTAC, a prominent player in the automotive testing, inspection and certification sector, is significantly broadening its footprint in China. The company has unveiled plans for a cutting-edge proving ground in Huainan, situated in the central province of Anhui. This ambitious project is being developed through a collaboration with the Huainan City Government and is set to become the primary strategic hub for the UTAC Group’s operations within the country. By establishing this facility, UTAC aims to bolster the mobility industry with top-tier testing capabilities and specialised knowledge.

The new site will enable UTAC’s team of specialists to offer homologation and testing services that align with the most current international benchmarks and regulatory standards. This initiative is a direct continuation of the group’s overarching goal to foster a mobility landscape that is both safer and more environmentally friendly. The Huainan facility is designed to be comprehensive, featuring a variety of specialised tracks for vehicle testing, along with a technology park that includes rentable workshops and office spaces. It will also house a dedicated conference and exhibition centre and purpose-built laboratories outfitted with state-of-the-art equipment. These labs will be specifically geared towards testing the latest advancements in new energy vehicles.

Anhui province itself provides a rich environment for such an investment. Home to 70 million people, it hosts a dense and extensive mobility ecosystem. Major automotive manufacturers like BYD, Changan, Chery, JAC, NIO and Volkswagen, together with their extensive supply networks, are deeply embedded in the region. The province’s manufacturing prowess is underscored by its production of roughly 3.7 million vehicles in 2023, a figure that positions Anhui as China’s leader in overall vehicle manufacturing, new-energy vehicle production and vehicle exports. Consequently, the new proving ground in Huainan is poised to become a vital strategic component for UTAC, solidifying its presence in this central hub of the Chinese mobility industry.

Connor McCormack, CEO, UTAC, said, " We are extremely proud of our partnership with the city of Huainan, which is undergoing a significant transformation to support the future of the automotive industry. UTAC is delighted to contribute to this transformation and to bring our 100 years of specialist expertise, along with the European standards we have helped shape and validate, to China’s vital automotive sector.”

Mayor Zhang Zhiqiang of Huainan City said, “This represents a significant milestone in Huainan's efforts to accelerate the development of its intelligent connected vehicle industry. It is of great importance in bridging the critical gap in the regional automotive sector’s industrial chain of ‘testing-production-export' and establishing a specialised vehicle testing and certification platform with international recognition. The successful cooperation on this project will undoubtedly advance the high-end and intelligent transformation of the regional automotive industry, providing strong impetus for Anhui Province's efforts to foster a new energy vehicle industrial cluster with international competitiveness.”

- DUNLOP Tyre Europe

- DUNLOP Tyres

- Sumitomo Rubber Industries

- DUNLOP BLUE RESPONSE TG

- Circuito de Sevilla

- Seville Driving Event

- Summer Tyres

DUNLOP To Showcase BLUE RESPONSE TG Summer Tyre At Seville Driving Event

- By TT News

- March 06, 2026

DUNLOP Tyre Europe GmbH (DUNLOP) is preparing to introduce its latest innovation, the BLUE RESPONSE TG, an all-new summer tyre engineered to advance safety, efficiency and driving dynamics. This model marks a significant milestone as the first DUNLOP summer tyre developed by Sumitomo Rubber Industries (SRI) and will make its official debut this weekend at the Circuito de Sevilla in Spain. The 4.2-kilometre track, known for its 16 corners and lengthy 822-metre straight, provides a demanding environment ideal for showcasing the tyre’s capabilities. Under the theme ‘the art of perfect balance’, the BLUE RESPONSE TG will undergo rigorous evaluation on the Spanish circuit to demonstrate its well-rounded performance.

A dynamic launch event has been arranged to give 120 attendees, including customers, journalists and influencers, a firsthand look at the tyre’s abilities across multiple conditions. Participants will engage in slalom exercises on both dry and wet surfaces, while braking and obstacle avoidance drills will highlight stopping power and responsiveness. Handling assessments will allow for direct comparison with rival products, focusing on cornering stability and steering accuracy. Additional tests will examine comfort and noise levels, emphasising rolling smoothness and sound reduction, as well as efficiency, showcasing lower rolling resistance and reduced fuel consumption. The experience will be complemented by guided road drives and track laps, offering a thorough perspective on the tyre’s dynamic qualities.

To illustrate the versatility of the BLUE RESPONSE TG, the test fleet includes a diverse selection of modern vehicles. Among them are the Audi e-tron, BMW 5 Series, Mercedes-Benz EQE, Mercedes-Benz G-Class, Toyota GR Yaris and Nissan GT-R R35, spanning from premium electric cars to high-performance sports machines. Developed specifically for contemporary vehicle platforms, the tyre integrates an advanced tread design, a novel rubber compound and a reinforced construction. These elements work together to deliver precise handling, short braking distances, strong wet grip and low rolling resistance, catering to drivers seeking safety, comfort and stability in both routine travel and more demanding scenarios.

Markus Bögner, President and Managing Director, DUNLOP Tyre Europe, said, “This is our first DUNLOP event since the acquisition, which is precisely why the launch of our summer tyre is so important to us. Direct interaction with customers and the media here on site is crucial for us, as it is the only way we can hear their perspectives and continue to develop in a targeted manner.”

Comments (0)

ADD COMMENT