Digital, Connected and Sustainable solutions will drive the future

- By TT News

- October 13, 2021

Until 1989, the IAA featured both passenger cars and commercial vehicles in one show that was held at the exhibition site in Frankfurt. Following a recent slump in visitor and exhibitor numbers, organisers VDA decided not to renew the contract with Messe Frankfurt and moved the show out of Frankfurt.

In March 2020, a decision was made to host the event in Munich due to it being home to manufacturers like BMW and several other tech companies like Apple and Google. The organisers also received support from the Greens-led city council and Bavarian state government to host the show. Due to the Covid-19 pandemic, the show was postponed from 2020 to 2021.

In March 2020, a decision was made to host the event in Munich due to it being home to manufacturers like BMW and several other tech companies like Apple and Google. The organisers also received support from the Greens-led city council and Bavarian state government to host the show. Due to the Covid-19 pandemic, the show was postponed from 2020 to 2021.

Finally, the show was held from 7-12 September 2021 in Munich. The move to Munich worked wonders for the organisers, as the 2021 edition of IAA Mobility witnessed over 400,000 participants from 95 countries, along with an international media reach of 137 billion. The show featured around 744 exhibitors and 936 speakers from 32 countries presenting their views and innovations.

Talking about the show's success, Hildegard Müller, President, German Association of the Automotive Industry (VDA), said, "We took a courageous step and were rewarded by the visitors. A total of 400,000 participants in only six days is a clear case of 'voting with their feet’. The visitors were evidently very interested in and delighted by the whole experience. The IAA MOBILITY is now the largest mobility event in the world. New electric cars, bicycles, e-scooters, energy policies and urban planning, digitisation and more – here in Munich, we presented and discussed what needs to be thought together in the future. At the IAA MOBILITY Conference, we also experienced lively discussions on the path to new mobility. The exhibitors unveiled more than 100 premieres of their latest models and concepts, underscoring the fact that the transformation of mobility is being driven forward toward climate neutrality and digitisation."

The 2021 edition of IAA Mobility was focused around 'What will move us next?'. Exhibitors presented their innovations focussing on automation, connectivity and sustainability. Below we will discuss the innovations displayed by Michelin and Continental and talk about the other significant exhibits from the show.

Continental:

It was a busy IAA Mobility 2021 for Continental. The company showcased a slew of innovations ranging from sustainable tyre to autonomous vehicle concept. All concepts showcased were categorised under the tagline 'Safe, Connected, Convenient and Driving the Future of Mobility for 150 years'.

It was a busy IAA Mobility 2021 for Continental. The company showcased a slew of innovations ranging from sustainable tyre to autonomous vehicle concept. All concepts showcased were categorised under the tagline 'Safe, Connected, Convenient and Driving the Future of Mobility for 150 years'.

The first concept showcased was the Conti GreenConcept. This sustainable tyre concept has been developed by Continental's development engineers and material experts to set new standards in integrated sustainability. The concept tyre consists of an exceptionally high proportion of traceable renewable and recycled materials. It is based on innovative and resource-saving lightweight technology that ensures an extended service life.

Conti GreenConcept tyre is made up of 35 percent renewable raw materials and 17 percent recycled materials. The use of organic materials like natural rubber from dandelions, silicate from the ashes of rice husks and various vegetable oils and resins help significantly in reducing the use of crude oil-based materials. In addition to using processed steel and carbon black, Continental is using recycled PET bottles in the casing of the tyre for the first time as part of its Contyre.Tex technology rollout.

Another advantage of the Conti GreenConcept’s lightweight design is significant reduction in rolling resistance helping improve EV range by up to six percent. According to an analysis by Continental, the rolling resistance of Conti GreenConcept is around 25 percent lower than any tyre with Class A rolling resistance. In addition, the Conti GreenConcept’s renewable tread can be replaced repeatedly with little effort. This tread concept significantly improves resource conservation along with improving the service life of the tyre.

Another advantage of the Conti GreenConcept’s lightweight design is significant reduction in rolling resistance helping improve EV range by up to six percent. According to an analysis by Continental, the rolling resistance of Conti GreenConcept is around 25 percent lower than any tyre with Class A rolling resistance. In addition, the Conti GreenConcept’s renewable tread can be replaced repeatedly with little effort. This tread concept significantly improves resource conservation along with improving the service life of the tyre.

Conti GreenConcept tyre also features COKOON – a technology for the eco-friendly bonding of textile reinforcements with rubber compounds developed by Continental in partnership with Kordsa.

Talking about the Conti GreenConcept tyres, Nikolai Setzer, CEO, Continental, said, "The cars of the future will still need tyres, which we are making more and more sustainable, as our concept tyre shows. The Conti GreenConcept demonstrates how Continental will completely convert its global tyre production to use sustainable materials by 2050 at the latest. This underlines our goal of being the most advanced tyre company along the entire value chain by 2030 in terms of social needs as well as our ecological and economic footprint. Step by step, our solutions and technologies are enhancing sustainability and climate protection on the road."

Continental also showcased its vision of an autonomous, connected future with the AMBIENC3 car interiors concept alongside the sustainable tyre concept. A combination of 'Ambience' and '3rd space', the AMBIENC3 concept combines driving, working and relaxing in one interior.

Continental also showcased its vision of an autonomous, connected future with the AMBIENC3 car interiors concept alongside the sustainable tyre concept. A combination of 'Ambience' and '3rd space', the AMBIENC3 concept combines driving, working and relaxing in one interior.

The interior concept features the Ac2ated sound system, offering immersive audio without speakers and the ProViu360 driver assistance system, which gives the driver much better situational awareness thanks to a camera surround system. Other exciting interior features include intelligent glass control with adjustable dimming and heating functions, a built-in solar charger with photovoltaic cell and the eTravel companion software that provides the driver with tips and recommendations relating to the route, refuelling and the condition of the vehicle.

Michelin:

While Continental stayed inside, Michelin took to the streets to showcase its airless tyre solution. Equipped on a Mini Electric, the Unique Puncture-Proof Tyre System (UPTIS) made its public appearance offering test ride opportunities to certain lucky members of the general public. Announced in 2019, the UPTIS is part of Michelin's sustainable development model, the Vision concept. The UPTIS features a structure capable of supporting the vehicle while also delivering a safe and comfortableride without air.

Commenting on the UPTIS, Cyrille Roget, Group Technical and Scientific Communications Director, Michelin, said, "The truly distinctive structure of the Michelin UPTIS prototype, or its 'weirdness' as we have often heard it called, really attracted the attention of many visitors and left a lasting impression on them. It was an exceptional experience for us, and our greatest satisfaction came at the end of the demonstration when our passengers, who were admittedly a little wary at first, said they felt no difference compared with conventional tyres."

Commenting on the UPTIS, Cyrille Roget, Group Technical and Scientific Communications Director, Michelin, said, "The truly distinctive structure of the Michelin UPTIS prototype, or its 'weirdness' as we have often heard it called, really attracted the attention of many visitors and left a lasting impression on them. It was an exceptional experience for us, and our greatest satisfaction came at the end of the demonstration when our passengers, who were admittedly a little wary at first, said they felt no difference compared with conventional tyres."

Along with the public display of the UPTIS, Michelin also showcased its first competition tyre constructed using 46 percent sustainable materials. These products align with Michelin's ambition to use 100 percent sustainable material in its tyres by 2050.

In addition to the tyre showcase, Michelin also ran an awareness campaign encouraging people to recycle waste and highlight the company's sustainability plans. Six teams were tasked to collect enough plastic to produce 100 tyres. The company has plans to utilise these PET bottles and yoghurt cups to produce and launch its first sustainable tyre latest by 2024. As part of its awareness campaign, Michelin also revealed a recipe for creating sustainable tyres using green waste and plastic waste.

Other launches

Apart from Continental and Michelin, there were many manufacturers and suppliers who showcased their vision of a carbon-neutral future. Some of the highlights include BMW's i Vision CirCular Concept car made from almost 100 percent recycled materials; automated valet parking system jointly developed by Bosch, Mercedes-Benz, BMW, CARIAD, Ford, Jaguar Land Rover, Continental, Valeo, Kopernikus Automotive and Unikie; driverless robotaxi for 2022 produced in collaboration by Intel and Sixt and multiple in-cabin monitoring systems for cars showcased by Valeo, Bosch and Continental.

Following a challenging phase with the ongoing pandemic, the auto industry has emerged greener and stronger than ever before and the IAA 2021 was an indication of the same. The next IAA Mobility show is scheduled from 5-10 September 2023 and we can expect the auto industry to come up with more intelligent and greener solutions to our mobility problems. (TT)

CEAT Drives Women’s Leadership And Inclusion Through Comprehensive Workplace Policies

- By TT News

- March 07, 2026

CEAT has introduced a comprehensive set of policies aimed at supporting the specific needs of its women employees and fostering their professional advancement. The organisation emphasises work-life balance as a means to enhance both personal well-being and workplace productivity, offering flexible remote work options in coordination with managers. A Wellness Leave policy allows women two days of monthly work-from-home or leave during menstruation without requiring justification, while shopfloor employees can access on-site Occupational Health Centres for shift changes or rest as necessary.

To cultivate leadership and career growth, CEAT has implemented targeted programmes such as Womentoring, the Women Accelerator Program and STARS, which focus on building digital, functional and leadership competencies. The EmpowHer Employee Resource Group further promotes inclusion and facilitates open dialogue within the organisation.

The company also provides extensive support for mothers, including 26 weeks of paid maternity leave, hospitalisation coverage and facilities such as crèches and lactation rooms across offices and plants. Returning mothers can benefit from flexible hours and a reduced four-hour workday until their child turns one, while shopfloor workers are assigned morning shifts during the first year after childbirth. A gender-neutral Child Caregiver Travel and Stay Policy ensures that caregiving responsibilities do not hinder career progression.

In manufacturing, CEAT has enhanced accessibility by introducing automated machinery, ergonomic fixtures and lift-assist devices. These changes have contributed to a 20 percent women workforce at the Chennai facility and 28 percent representation on the Nagpur shopfloor, which was the first in Maharashtra to introduce night shifts for women. Safe transport, women security personnel and ergonomic workplace design further support this inclusion. Collectively, these efforts reflect CEAT’s commitment to enabling women to lead and succeed in diverse roles.

ZC Rubber Exhibits Industrial And OTR Tyre Solutions At CONEXPO 2026

- By TT News

- March 07, 2026

ZC Rubber is showcasing an extensive selection of industrial and off-the-road tyre solutions at the CONEXPO-CON/AGG 2026 trade show, being held from 3 to 7 March 2026 in Las Vegas. Attendees can visit the company at booth #N11041 in the North Hall to explore products from its key brands, including WESTLAKE, TIANLI, ARISUN and YONGGU. These offerings are specifically engineered to withstand the rigorous demands of sectors such as construction, agriculture, forestry and material handling.

The display features a comprehensive range of products, such as radial OTR tyres, agricultural tyres, forest tyres, material handling tyres and rubber tracks. Each product is designed to deliver durability, superior traction and operational efficiency in challenging work environments. The exhibition provides an important platform for ZC Rubber to engage with industry professionals, highlight its technological advancements and demonstrate its commitment to supporting global construction and industrial sectors with reliable, high-performance solutions.

Visitors can explore the lineup and speak with the team to learn how these tyre solutions can enhance productivity across a wide variety of applications.

Benjamin Lou, Global OTR Director, ZC Rubber, said, “CONEXPO brings together the people and machines that keep the world building, and it’s a great place for us to connect with customers face-to-face. With brands like WESTLAKE, TIANLI, ARISUN and YONGGU under one roof, we’re able to offer a true one-stop tyre solution across construction, agriculture, forestry and material handling. Our goal is simple – help customers find the right tyre for every job, all in one place.”

Bridgestone Develops Industry-First TRWP Vehicle Collection Method For Trucks And Buses

- By TT News

- March 07, 2026

Bridgestone Corporation has announced a significant advancement in environmental research with the development of an industry-first vehicle collection method for tyre and road wear particles (TRWP) specifically from truck and bus tyres. This innovation is designed to enhance scientific understanding of how such particles may interact with the environment. Tyre and road wear particles are generated through the friction between a tyre’s tread and the road surface – a process essential for vehicle safety and comfort – and consist of a combination of worn tyre material and fragments of road pavement. The newly developed collection method for trucks and buses was also showcased at the Tire Technology Expo 2026, held from 3 to 5 March in Hannover, Germany.

The company had previously introduced a collection method for passenger car tyres in 2025 and has since been working to improve its efficiency. Applying insights gained from that earlier development, particularly regarding how particles are generated and dispersed, Bridgestone created a proprietary system tailored to the larger scale of truck and bus tyres. To ensure the accuracy of the collected samples, the company used a dedicated proving ground designed to replicate real-world driving conditions. Before each test, the track was meticulously cleaned to prevent contamination from pre-existing debris.

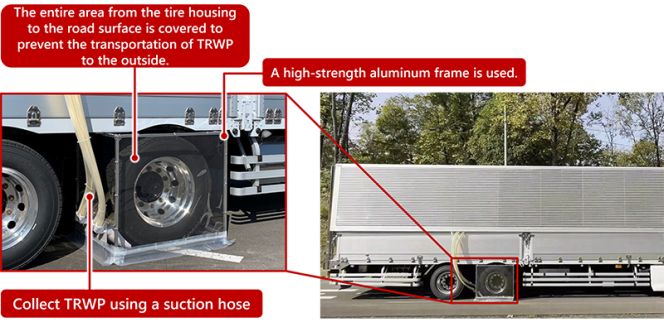

For the collection process, Bridgestone engineered suction devices and intake mechanisms compatible with larger tyres. A sturdy aluminium frame was used to construct the tyre cover, ensuring durability against strong winds during operation. Following controlled driving sessions, particles that remained both on the track surface and inside the tyre cover were gathered for analysis.

This effort is part of a broader commitment to investigate the physical and chemical characteristics of tyre wear particles and their potential environmental effects. Bridgestone participates in the Tire Industry Project (TIP) facilitated by the World Business Council for Sustainable Development and collaborates with external research organisations and corporate partners. With the ability to collect samples from both passenger vehicles and heavy-duty trucks and buses, the company aims to accelerate research, share findings widely and support efforts to reduce particle generation.

Alongside this research, Bridgestone is advancing several complementary initiatives. These include developing longer-lasting tyres with improved wear resistance, offering solutions that help customers lower total operating costs and working to minimise environmental impact throughout the product lifecycle.

UTAC Expands In China With New EV-Focused Proving Ground In Anhui

- By TT News

- March 07, 2026

UTAC, a prominent player in the automotive testing, inspection and certification sector, is significantly broadening its footprint in China. The company has unveiled plans for a cutting-edge proving ground in Huainan, situated in the central province of Anhui. This ambitious project is being developed through a collaboration with the Huainan City Government and is set to become the primary strategic hub for the UTAC Group’s operations within the country. By establishing this facility, UTAC aims to bolster the mobility industry with top-tier testing capabilities and specialised knowledge.

The new site will enable UTAC’s team of specialists to offer homologation and testing services that align with the most current international benchmarks and regulatory standards. This initiative is a direct continuation of the group’s overarching goal to foster a mobility landscape that is both safer and more environmentally friendly. The Huainan facility is designed to be comprehensive, featuring a variety of specialised tracks for vehicle testing, along with a technology park that includes rentable workshops and office spaces. It will also house a dedicated conference and exhibition centre and purpose-built laboratories outfitted with state-of-the-art equipment. These labs will be specifically geared towards testing the latest advancements in new energy vehicles.

Anhui province itself provides a rich environment for such an investment. Home to 70 million people, it hosts a dense and extensive mobility ecosystem. Major automotive manufacturers like BYD, Changan, Chery, JAC, NIO and Volkswagen, together with their extensive supply networks, are deeply embedded in the region. The province’s manufacturing prowess is underscored by its production of roughly 3.7 million vehicles in 2023, a figure that positions Anhui as China’s leader in overall vehicle manufacturing, new-energy vehicle production and vehicle exports. Consequently, the new proving ground in Huainan is poised to become a vital strategic component for UTAC, solidifying its presence in this central hub of the Chinese mobility industry.

Connor McCormack, CEO, UTAC, said, " We are extremely proud of our partnership with the city of Huainan, which is undergoing a significant transformation to support the future of the automotive industry. UTAC is delighted to contribute to this transformation and to bring our 100 years of specialist expertise, along with the European standards we have helped shape and validate, to China’s vital automotive sector.”

Mayor Zhang Zhiqiang of Huainan City said, “This represents a significant milestone in Huainan's efforts to accelerate the development of its intelligent connected vehicle industry. It is of great importance in bridging the critical gap in the regional automotive sector’s industrial chain of ‘testing-production-export' and establishing a specialised vehicle testing and certification platform with international recognition. The successful cooperation on this project will undoubtedly advance the high-end and intelligent transformation of the regional automotive industry, providing strong impetus for Anhui Province's efforts to foster a new energy vehicle industrial cluster with international competitiveness.”

Comments (0)

ADD COMMENT