HOW IT CREATES A FUTURE- PROOF TYRE MANUFACTURING…

Conventional tyre manufacturing systems require too much human skill and intervention, so the impact and consequences of digitalisation on the tyre industry are even greater. Standard manufacturing processes require strict monitoring, corrections and automation at every stage. Digitalisation offers numerous benefits for sustainable production improvements. They achieve measurable results in manufacturing, quality improvement, marketing and sales.

Tyre manufacturers monitor and automate their processes, reduce manual labour and gain real-time insights into production line status and performance. Barcode and QR code labelling streamlines production processes, enables efficient and cost-effective tracking and improves accuracy and efficiency. Traceability is simple and feasible, improving profitability and customer satisfaction.

Scanning simplifies the location, tracking of parts and materials and provides manufacturers with real-time insights into their production processes. RFID applications are gaining momentum in the passenger tyre segment, having already demonstrated numerous benefits in commercial applications.

Digitalisation technologies help quick identification of production defects in the final product and increase productivity with AI based scanning, inspection, real-time decision-making processes.

Digitalisation in the tyre industry is a gradual process that will improve performance, quality and profitability being on the way of real Industry 4.0 applications in tyre manufacturing. It continually opens up new opportunities to leverage data for better decision-making. Overall, digitalisation in tyre manufacturing is a powerful tool that unlocks the full potential of production. However, after implementation, continuous investment, as well as internal research and improvements, are required.

The tyre manufacturing industry is constantly evolving. Machines are becoming increasingly automated, more precise and data-driven. Recent advances based on the principles of Industry 4.0 include the aforementioned IoT, AI (artificial intelligence), robotics and sustainability.

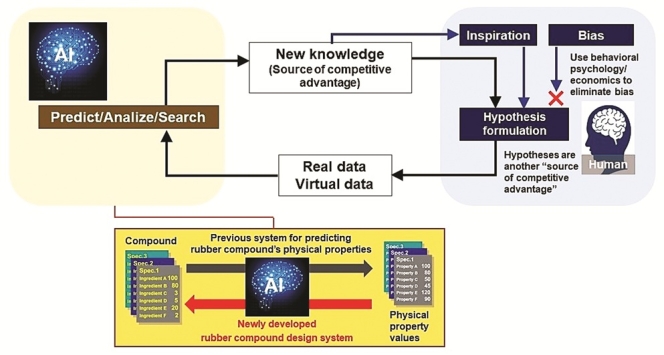

Industry 4.0-driven digitalisation is based on the concept of the ‘digital twin’, meaning every machine is a data node. Data from every step (compound parameters, component dimensions, curing profiles) is collected for each tyre. This creates a virtual replica of the physical tyre, which is a ‘digital twin’ that enables complete traceability and data-driven process optimisation.

The role of humans is evolving from simple manual tasks to monitoring, diagnostics and data analysis. Robots, especially collaborative robots or cobots,

are taking over tasks such as final inspection and material handling. These revolutionary steps and concepts are having a major impact on manufacturing, optimising quality, performance, customer satisfaction and contributing to business success.

Modern mixing systems are increasingly replacing conventional tangential mixers. The intermeshing of the two rotors ensures more efficient and homogeneous mixing with better temperature control. This leads to higher mixing quality and consistency.

New mixing technologies, on the other hand, utilise ‘continuous mixing systems’, i.e. the continuous and simultaneous supply of all raw materials in precisely controlled quantities. The materials are continuously mixed in a series of specialised extruders and mixing units. At the end, a continuous stream of a perfectly homogeneous mixture emerges. This represents a revolution compared to conventional batch mixing. It improves energy efficiency, reduces the carbon footprint and enables unprecedented consistency and traceability.

Highly automated ‘multi-calender systems’ are equipped with multiple rollers that can simultaneously produce multiple layers (e.g. carcass ply, squeegee layer or inner liner) with extreme precision in thickness and width. Similar to extrusion lines with laser thickness control, these systems ensure 100 percent control and transmit data immediately to the extrusion head and calender roll clearances for automatic adjustment and maintenance of tolerances down to a fraction of a millimetre.

Thanks to the ‘multi-stage transfer’, the tyre casing is transferred between drums for the various production steps automatically and without human intervention, automatic cutting and splicing prevent deviations in quality. RFID technology integrated fully assures correct recipe and security in component application.

The robotic application and component preparation, such as with 6-axis robots, is now widely used for the fast and precise gripping and placement of complex components such as bead and apex assemblies.

Electric vulcanising presses are equipped with intelligent mould controls, whose integrated sensors monitor temperature and pressure in real time across multiple zones. The AI system dynamically adjusts the vulcanisation cycle (time, temperature, steam pressure) to ensure perfect curing of each tyre and compensate for any mould or material deviations.

Furthermore, predictive maintenance is now essential to avoid unplanned production downtime. Vibration, temperature and pressure sensors installed on manufacturing machines monitor all machine functions and alert when maintenance is required. High-precision servomotors, replacing pneumatic or hydraulic systems, work with servo-electric robots and are used in various production phases with submillimetre precision, reducing energy consumption and maintenance requirements.

The most visible technological advances in finishing and inspection lines today are fully automated with full sensitive cameras, AI-integrated and non-destructive testing (NDT) machines. Automated high-resolution X-ray machines scan each tyre to detect hidden defects such as trapped air, steel cord separation, or bead wire issues. Shearography and holography – being traditional but now equipped with intuitive, incredibly fast and precise modes – use lasers and intelligence to detect underlying defects or separations by measuring stress-induced deformations.

Uniformity and force variation measurement systems utilise AI algorithms to not only identify a tyre as ‘good’ or ‘bad’ but also diagnose the root cause of the deviation. Robotic trimming and polishing machines automatically locate and remove burrs (excess rubber) from the tyre using precise grinding tools – a traditionally manual and laborious task.

Of course, the future of tyre manufacturing, driven by advanced digitalisation, IoT and robotics, is rapidly evolving into a model for a smart, autonomous and sustainable industry, often referred to as ‘Tyre Industry 4.0’.

This transformation isn’t just about doing the same things faster; it will fundamentally change tyre design, production, sales and even performance. Tyre production facilities will become more autonomous, adaptable, efficient, predictive, personalised and, as expected, more sustainable.

Industry 4.0 and AI-powered digitalisation will accelerate sustainability. Precision manufacturing minimises material waste through the use of high-precision components. AI can easily manage energy consumption throughout the factory. IoT sensors monitor the overall condition of tyres, ensuring fast tyre changes, safety and performance.

This transformation will lead to safer, more efficient and more environmentally friendly tyres.

Hankook Tire Appoints New VP Of Marketing For North America

- By TT News

- January 23, 2026

Hankook Tire has appointed Seunghwan (Aaron) Hong as Vice President of Marketing for its North America Headquarters in Nashville. He assumes this position following the promotion of Kyuwang (Ken) Cho, who is now leading the company’s Global Truck & Bus Division from Seoul.

In his new capacity, Hong will be responsible for North American marketing strategy, technical services, Canadian operations and supply chain logistics, focusing on strengthening the brand’s support for regional tyre dealers. Hong’s extensive two-decade career with Hankook includes leadership roles such as Managing Director in Canada and the Netherlands, along with a strategic position in the Global TB sales division.

Cho, who previously served as Senior Vice President of Sales and Marketing in North America, returns to Korea, where he had earlier held a senior global sales role within the TB division.

Rob Williams, President, Hankook Tire America Corp., said, "We're thrilled to welcome Aaron to Nashville as our new Vice President of Marketing. He brings a wealth of global experience and a proven ability to drive growth across diverse markets. As we continue to expand our brand and strengthen relationships with our dealers throughout North America, Aaron's strategic vision will be key to advancing Hankook's innovation and performance in the tyre market. We are appreciative of Ken's leadership over the past year in elevating our presence across both consumer and commercial channels."

Scandinavian Enviro Systems Appoints Fredrik Aaben As New CEO

- By TT News

- January 23, 2026

Scandinavian Enviro Systems has appointed Fredrik Aaben as its new Chief Executive Officer effective 16 January 2026. He succeeds Fredrik Emilson, who is stepping down from the role by mutual agreement. Emilson will remain with the company in a supportive capacity, serving as a Senior Advisor during the transitional period.

Aaben brings substantial financial and strategic experience to the position, having served as the company’s Chief Financial Officer since November 2024. His prior career includes close to eight years at Volvo Cars, where he most recently held the position of Head of Corporate Finance and gained extensive experience in finance, strategy and governance. His background also includes roles as Group Business Controller at Stena AB and work in management consulting. Aaben holds dual Master of Science degrees in Industrial Engineering and Management and in Software Engineering from Chalmers University of Technology.

Concurrent with this change, Maria Ljungstrand has been promoted to Chief Financial Officer. She joined Scandinavian Enviro Systems in April 2024 as Head of Group Business Control and previously held business controller positions at Danone and Mondelez International.

The Board of Directors expressed gratitude to outgoing CEO Fredrik Emilson for his dedication and valuable contributions. Under his leadership, the company achieved significant developmental milestones, and the Board acknowledged his considerable efforts and commitment.

Ewa Björling, Chairman of the Board of Scandinavian Enviro Systems AB (publ), said, “The Board is very pleased to appoint Fredrik Aaben as Chief Executive Officer of Scandinavian Enviro Systems. Fredrik has a deep understanding of the company, its operations and strategic direction, and has demonstrated strong leadership, analytical capability and commitment during his time as Chief Financial Officer. With his extensive experience in finance, strategy and corporate governance, the Board has very strong confidence in Fredrik’s ability to lead Enviro forward and successfully drive the company’s continued development and growth.”

Aaben said, “I am excited to have been appointed Chief Executive Officer of Scandinavian Enviro Systems. Enviro is a company with a leading technology platform and a highly competent organisation. I look forward to working closely with the Board, the management team and all employees to drive execution and continue developing the company in line with its long-term ambitions.”

Dunlop Aircraft Tyres Names Lee Timbrell As New CCO

- By TT News

- January 23, 2026

Dunlop Aircraft Tyres, a leading independent global designer and manufacturer of high-performance aircraft tyres serving the commercial, military and freighter aircraft markets, has named Lee Timbrell as its new Chief Commercial Officer. In this position, he will oversee all global commercial functions such as sales, strategy, business development and customer relations.

Timbrell arrives from Safran Actuation Systems, where he most recently served as Senior Director of Aftermarket Services. There, he managed aftermarket sales and profitability across nine MRO facilities, led a large team and oversaw profit and loss for those operations. His background also includes senior commercial roles at Collins Aerospace, Cathay Pacific Airways and Turner Aviation.

Academically, Timbrell holds an MBA and a Postgraduate Certificate in Management from the University of Northampton, complemented by a Bachelor of Engineering in Aeronautical Engineering from Loughborough University. His experience was instrumental during the corporate transition when Safran acquired the actuation business from Collins Aerospace.

Susan McKenna, Chief Executive Officer, Dunlop Aircraft Tyres, said, "I'm delighted to welcome Lee to the Dunlop team. He joins us at a pivotal moment in our more than 100-year operating history, following strong financial performance in 2025 and the recent completion of our USD 93 million senior secured bond offering, which strengthens our balance sheet and provides added flexibility to support our future growth strategy. Lee brings extensive global aftermarket and customer leadership experience, with a proven record of driving growth and strengthening long-term partnerships. Having previously worked with Lee at Collins Aerospace, I am confident that his commercial expertise and deep industry knowledge will help accelerate Dunlop's next phase of growth."

Timbrell said, "I am thrilled to join Dunlop to elevate further the strong brand equity the company has established in the aviation industry over more than a century. I look forward to working with the team to advance the company's commercial strategy and deliver long-term value for our global customers and stakeholders."

Nokian Tyres Launches Betula Concept Tyre With Renewable Birch-Based Compound

- By TT News

- January 22, 2026

In a notable stride towards sustainable tyre manufacturing, Nokian Tyres has introduced the Betula concept tyre, which incorporates a pioneering compound derived from birch bark. This renewable substance is produced by the Swedish firm Reselo, which transforms residual matter from the global pulp, paper and plywood sectors into a viable tyre ingredient. For the first time, this birch-based material has been integrated into a tyre's tread compound, contributing to a tread where recycled and renewable resources now constitute 93 percent of all materials used.

This innovation is viewed as a way to enhance tyre performance. The Betula concept, which utilises the tread pattern of Nokian's Hakkapeliitta R5 winter tyre, has undergone successful testing at the company’s facilities in Ivalo, Finnish Lapland, and in Nokia, Finland. The project marks meaningful progress towards Nokian Tyres’ target of having 50 percent recycled and renewable materials in its tyres by 2030, aiming to establish new environmental standards for the industry through such pioneering efforts.

The collaboration with Reselo originated in 2023 when the biomaterials company won Nokian Tyres’ sustainable innovation challenge. A formal development agreement followed in 2024 to refine the renewable material for tyre applications, and joint development continues even after the concept tyre’s launch.

Concept tyres like the Betula are vital to Nokian’s development process, allowing new materials and technologies to be evaluated before commercial release. This approach has yielded several advanced prototypes, including the 2022 Green Step concept, which also achieved 93 percent renewable or recycled content, and the 2024 Green Step Ligna, featuring a renewable lignin-based alternative to carbon black. The company’s commitment is already reflected in production models, exemplified by the 2025 Nokian Seasonproof 2 all-season tyre for Central Europe, which contains up to 38 percent recycled and renewable materials – the highest proportion in the company’s current commercial lineup.

Teemu Soini, Vice President – Innovations & Development, Nokian Tyres, said, “Since the early stages, the potential of the material to be used in tyres has been evident. The Nokian Tyres Betula concept tyre confirms its applicability and highlights the material’s potential for commercial use in the future. Furthermore, the material is not only sustainable, but according to our testing, it also shows promise to improve tyre performance.”

Josefin Larsson, CEO, Reselo, said, “For Reselo, this partnership represents much more than a technical development project. The tyre industry’s sheer scale and traditionally conservative approach make it a challenging but vital space for rubber innovation, and seeing the collaboration with Nokian Tyres continue to the next level is something we’re especially proud of. Birch bark is a high-volume forestry side-stream abundant in the Nordics, and step by step, we are working together towards better-performing and more sustainable products with circularity at the core.”

Comments (0)

ADD COMMENT