Powering Retrospection In Tyres Through Tags

- By Sharad Matade & Gaurav Nandi

- July 01, 2025

The integration of Radio Frequency Identification (RFID) technology into the tyre industry is gaining momentum, offering solutions for traceability, sustainability and lifecycle management. Beontag, in collaboration with Michelin, is spearheading this innovation by jointly designing specialised RFID tags that can withstand the harsh conditions tyres face, such as extreme heat and pressure. The tags store crucial data, enabling efficient recycling, retreading and warranty management. As the tyre industry evolves, RFID adoption is seen as essential for ensuring authenticity, improving asset management and supporting regulatory frameworks. However, challenges remain in scaling production and increasing industry awareness.

Punch card systems, barcodes, dog tags, biometric scanners etc. are all instruments that offer basic information about humans and commodities for identification, authentication, traceability and retrospection.

The tyre industry is similarly standing at a crossroad where the demand for traceability and retrospection is growing. Tyre manufacturers, retailers, retreaders and recyclers are showing a growing exuberance for digital footprints that can record, summarise and authenticate information related to each existing and new tyres throughout the commodities lifecycle.

And the simple solution catering to such demands is a radio frequency identification (RFID) tags. While the use of RFID tags is new within the global tyre market, these have found a stronghold across retail, logistics, manufacturing, healthcare etc.

The tag is changing the game of traceability within tyre markets as the adoption grows. Technological companies are collaborating with tyre manufacturers to develop tailor-made RFIDs.

International RFID and IoT expert Beontag is one such company that has developed RFID tags for the tyre industry. Divulging deep into the engineering mechanics of the tag, APAC Senior Sales Manager Evelyn Ong told Tyre Trends, “RFID technology used in tyres is significantly different from conventional RFID applications due to the harsh conditions tyres endure, such as high temperature, pressure and wear and tear. Unlike RFID tags used in retail or medical settings, tyre RFID tags must be engineered to survive extreme conditions. As a result, traditional RFID designs, which use PET labels and conductive paste for chip attachment, are unsuitable. Instead, tyre RFID tags rely on a mechanically robust and inductively coupled antenna structure.”

“Designing RFID for tyres required a completely new approach, and the current version (generation four) is believed to be durable enough to last the entire lifecycle of a tyre. This innovation aligns with initiatives like the European Digital Product Passport (DPP), which mandates that products must be identifiable throughout their life cycle. Although RFID chips themselves only store a unique identifier (similar to a FASTag or car license plate), all detailed data such as manufacturing date, plant origin, distribution history, usage, retreading details and material composition is stored in backend software systems. As the tyre moves through the supply chain, each stakeholder adds relevant data to the software based on the RFID, creating a comprehensive database that supports traceability and lifecycle management including recycling or retreading,” she added.

The company’s main RFID tag for the tyre industry includes a chip with memory, enabling it to store data and serve as a digital identifier for the physical tyre using radio waves. This transforms a traditional tyre into a digitally traceable product.

Beontag jointly designed this RFID tag with Michelin, exploring the benefits of embedding a chip in tyres for purposes like asset management and product authentication and was instrumental in driving standardisation across the industry. While Michelin is the first tyre manufacturer to roll out the new ‘smart tyres’ with Beontag technology, the manufacturer recently announced a partnership with Kumho Tire and aims to go into partnership with other brands in the near future.

DEMAND AND SUPPLY

The company recently participated in a global tyre exhibition and rationalised its participation with significant long-term potential of the tyre RFID market. “With over 30 billion tyres in circulation globally, the scale of the opportunity is enormous. Having worked in RFID for over 20 years, the technology excels in applications involving products that are physically similar and difficult to differentiate visually like tyres. This makes tyres an ideal use case for RFID,” said the official.

Ong explained that beyond the European Digital Product Passport regulation, a key driver for embedding RFID in tyres is the fundamental need for every product to have a unique identity, whether through a barcode, QR code or digital tag. In the tyre industry, this need has been especially pressing due to the limitations of traditional identification methods like hot stamping, which often wear off over time and result in a loss of traceability.

Ong explained that beyond the European Digital Product Passport regulation, a key driver for embedding RFID in tyres is the fundamental need for every product to have a unique identity, whether through a barcode, QR code or digital tag. In the tyre industry, this need has been especially pressing due to the limitations of traditional identification methods like hot stamping, which often wear off over time and result in a loss of traceability.

She noted that the absence of a durable, readable ID creates challenges in verifying authenticity, determining warranty status and tracing the tyre’s origin. For instance, without a reliable identifier, it becomes difficult to confirm whether a tyre is genuinely from Michelin or to retrieve key manufacturing details such as plant location, batch number or intended distribution path.

By embedding RFID tags with unique digital identities, the industry gains the ability to link every part of the tyre’s lifecycle across the value chain. This ensures consistent traceability, facilitates better inventory and warranty management and combats counterfeiting.

“We are actively engaging with the top 10 global tyre manufacturers in the transition towards RFID-enabled tyres. While the European market is leading adoption driven largely by regulatory frameworks, we are also working with tyres manufacturers across the Asia-Pacific region and beyond.

“Although OEMs like Michelin are beginning to integrate RFID tags, starting with high-end passenger tyres, there is a growing and immediate demand from the aftermarket. This secondary market includes fleet operators, leasing companies and pay-per-use models, where the need for tyre tracking is urgent. These businesses want to monitor retreading cycles, ensure asset recovery and verify ownership, especially to prevent tyre theft or unauthorised replacements,” she added.

According to Ong, some aftermarket players are even looking to embed RFID tags independently rather than waiting for OEMs to standardise the process, underscoring strong demand outside the traditional supply chain.

When asked about growth potential between the passenger and commercial segments, she indicated that although current OEM efforts are focused on high-end passenger tyres, interest from the commercial and aftermarket sectors is strong and could drive faster adoption due to practical and financial incentives.

Furthermore, RFID tags play a key role in sustainability by enabling traceability throughout a tyre’s lifecycle. It allows manufacturers to capture crucial data at the point of manufacture, which is essential for tracking and recycling. With RFID, recycling processes become more efficient because tyres can be easily sorted based on type, size and materials. This minimises waste, reduces sorting time and improves the overall effectiveness of recycling efforts.

HURDLES IN ADOPTION

The executive noted that there are unique challenges of designing an RFID tag for tyres given the nature of its operations. To address these hurdles, the company and Michelin jointly designed and extensively validated a specialised RFID tag consisting of a chip and an antenna, which is fully embedded within the tyre.

This tag is designed to be invisible from the outside and integrated into the tyre structure in a way that ensures durability without compromising performance. The antenna’s spring-like structure allows it to expand and contract along with the tyre’s movement without affecting its function.

Crucially, the connection between the chip module and spring antenna is linkless, using inductive coupling instead of mechanical connection. This inductive mechanism ensures reliability even under extreme conditions like high temperature, pressure and physical deformation.

Although the tag is not constantly read during vehicle operation, it must remain functional and readable during inspections or servicing.

Alluding to broader industry challenges towards adoption, Ong said, “Current challenges centre primarily around a lack of awareness and industrialisation of the production process in existing tyre production lines and factories. Unlike retail, where RFID is well-established, the tyre sector is still in the early stages of adoption. Because of this, there is a need to educate the market, build trust and demonstrate real-world use cases. Potential customers are hesitant to act as first movers and prefer to see proven implementations to reduce perceived risk. A hopeful future challenge would be demand outpacing production capacity. However, a more realistic and significant long-term challenge lies in technological evolution, particularly around IC size, performance development and adding more functionality through sensor information.”

INTEGRATING RFIDS

The RFID chip used in tyres stores a minimum of 96 bits of data, which aligns with the standard size modelled after barcodes. This size is sufficient to encode essential identifying information including a serialised number.

While barcodes only identify products at the SKU level, RFID allows each item to have a unique identifier, making it far more powerful for inventory management. At every stage in the tyre’s lifecycle, it is the responsibility of the user or stakeholder to read the RFID tag and input relevant data into the software system, linking it to the tag’s unique identifier.

One of the most compelling applications of tyre RFID is during the tyre’s second life – especially in retreading. In this stage, the retreader can embed a new RFID tag and effectively reset the tyre’s lifecycle. This allows the retreading company to claim and track the work they’ve done including how many times the tyre has been retreaded and when.

Fleet operators or regulators can use this data to verify authenticity, ensure compliance and manage safety.

At the end of the tyre’s life, especially during the recycling stage, RFID continues to offer value by recording the tyre’s complete journey. Recyclers can access a tyre’s full history by ensuring proper handling and reporting.

The key challenge in placing the RFID tag is ensuring its proper location and integration into the tyre’s structure. This process must be carefully controlled as the tag must not only be positioned in the optimal spot but also withstand the stresses and heat of the curing process. If the tag was placed improperly, it could potentially cause issues with its performance, especially in terms of readability after the tyre is fully cured and ready for use.

COMPETITION AND EVOLUTION

Besides Beontag, there are other companies operating within the tyre RFID space. Alluding to the distinction between them, Ong explained, “The main difference of our product lies in the patented POD design (POD = IC module/package). Our product utilises a special alloy for the antenna, which prevents deformation and ensures consistent diameter and gap size. Additionally, the chip packaging has been specifically designed to offer better protection, reducing the risk of damage and ensuring reliable readings.”

She explained that the company’s business case for RFID technology in the tyre industry is clear and it believes strongly in its potential. She emphasised the importance of spreading awareness about the technology, as Europe will be implementing the technology first, but other regions including APAC and the Americas will be catching up as the technology is proven in the coming years.

- Global Data Service Organisation for Tyres and Automotive Components

- GDSO

- RAIN Alliance

- RAIN RFID

- Digital Tyre Identification Standards

GDSO And RAIN Alliance Join Hands To Advance Digital Tyre Identification Standards

- By TT News

- February 13, 2026

The Global Data Service Organisation for Tyres and Automotive Components (GDSO) has entered into a Memorandum of Understanding with the RAIN Alliance, a move designed to accelerate the harmonisation of electronic tyre identification and support broader digitalisation throughout the international tyre value chain. This agreement formalises a mutual commitment to advancing interoperable, scalable and globally consistent standards that can be adopted across the sector.

GDSO is responsible for establishing and promoting global data standards for tyres, enabling comprehensive lifecycle applications that serve a diverse group of stakeholders – from manufacturers and logistics providers to fleet managers, recyclers and regulatory bodies. The RAIN Alliance, in parallel, champions the widespread implementation of RAIN RFID technology within a framework that is open, standards-based and interoperable.

The growing importance of electronic tyre identification is underscored by its role in enabling traceability, meeting regulatory requirements, advancing circular economy goals and improving operational performance. Within existing standardisation frameworks, embedded RAIN RFID technology is currently the sole passive data carrier capable of supporting item-level traceability across the full lifespan of a tyre. This partnership seeks to align data standardisation efforts with the underlying identification technologies, thereby reinforcing the ecosystem necessary for reliable and scalable digital identification solutions worldwide.

Although GDSO acknowledges the established position and technical maturity of RAIN RFID, the organisation maintains a technology-agnostic stance. Its primary focus remains on developing robust and adaptable global data standards that foster an inclusive and resilient identification ecosystem. Such an approach supports ongoing innovation and ensures that all actors across the tyre value chain can participate effectively, regardless of future technological shifts.

Through this alliance, GDSO and the RAIN Alliance intend to drive globally aligned standards, enhance system interoperability, support digital use cases throughout the product lifecycle and contribute meaningfully to sustainability and circularity targets. This partnership reflects a shared strategic vision to strengthen the digital infrastructure underpinning the tyre industry.

Riccardo Giovannotti, Secretary General, GDSO, said, “I’m pleased to share that GDSO has signed a collaboration MoU with RAIN Alliance. The collaboration is grounded in a shared commitment to industry-wide standards and to advancing digitalisation across the tyre value chain. As the organisation leading the definition and deployment of global data standards for tyres, GDSO focuses on enabling cradle-to-grave use cases through interoperable and scalable solutions. Within today’s standardisation landscape, the embedded RAIN RFID (i.e. passive RFID) is currently the only data carrier standardised and technically capable of supporting item-level identification across the full tyre lifecycle, which makes this collaboration both relevant and timely.”

- Titan International

- Cerebrum Sensor Technologies

- Pressure Perfect

- P2

- Intelligent Tyre Solutions

- Agricultural Tyre Intelligence

Titan And Cerebrum Unveil Pressure Perfect, A Breakthrough In Agricultural Tyre Intelligence

- By TT News

- February 11, 2026

A new milestone in agricultural tyre technology has been achieved through the partnership of Titan International, Inc. and Cerebrum Sensor Technologies, Inc. Together, they have unveiled Titan Pressure Perfect (P2), a smart sensor system designed to transform how farm tyres perform and communicate. This system marks the emergence of a broader category known as Intelligent Tyre Solutions (iTS), developed jointly by the two companies.

At the core of Pressure Perfect (P2) is real-time monitoring of tyre pressure, temperature and load. This data enables continuous oversight and works seamlessly with onboard inflation systems, allowing automatic pressure adjustments while the vehicle is in motion. Whether shifting from roadway to field or responding to varying load demands, the system can reduce air pressure by as much as half. This flexibility helps lower soil compaction by up to 35 percent and has been linked to potential corn yield increases of four to six percent.

Pressure Perfect is compatible with all Titan and Goodyear Farm Tyre products and integrates with nearly all inflation management systems already in use. By supporting more precise tyre management, it contributes to longer tyre life, improved machine efficiency and reduced environmental impact through less ground disturbance.

The innovation draws on Cerebrum’s licensed portfolio of patented technologies, including advanced sensors, proprietary algorithms and sophisticated software capabilities. This technical foundation sets a new standard for intelligent tyre management in agriculture. While other industry players focus on replicating existing central tyre inflation and tyre pressure monitoring systems, Titan and Cerebrum are advancing a more comprehensive and forward-looking approach. Pressure Perfect reflects Titan’s longstanding engineering heritage and its continued commitment to leading the field through purposeful collaboration and applied innovation.

Dubbing it the ‘Holy Grail’ of innovations, Scott Sloan, Global Ag & LSW Product Manager for Titan, said, “This is the first system of its kind that delivers dynamic inflation management. Load, tyre pressure and temperature data are gathered by a single tyre-mounted sensor and integrated with tyre-industry load-inflation tables in real time. Imagine bringing together Central Tyre Inflation System (CTIS) and Tyre Pressure Monitoring System (TPMS) technologies, and now they can work together and talk to each other – all without operator intervention."

Anyline Displays TireBuddy Platform At NADA 2026

- By TT News

- February 04, 2026

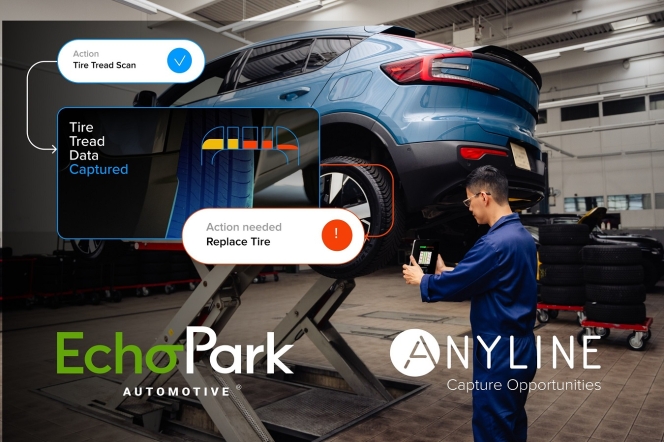

Anyline is displaying its AI-powered TireBuddy platform at the 2026 National Automobile Dealers Association (NADA) Show in Las Vegas (from 3–6 February), demonstrating how it brings objective, digital tyre inspections to automotive retailers. The technology, which standardises tread depth and condition assessments, is used by dealerships, reconditioning centres and independent shops to enhance operational consistency and customer transparency. At Booth 7649N, live demonstrations will show the system’s guided scanning and intuitive workflow, which technicians have adopted for its ability to generate clear, data-backed reports directly in the service bay.

A key adopter includes EchoPark, a national pre-owned vehicle retailer under Sonic Automotive, Inc., which utilises TireBuddy as part of its rigorous 190-point vehicle inspection process across multiple states. The platform provides repeatable measurements that strengthen technical recommendations and build buyer confidence by turning subjective checks into documented insights. Since its 2025 launch, the tool has been implemented by large-scale automotive groups seeking to improve decision-making and efficiency.

Anyline’s exhibition will focus on these real-world applications, showing how digitising tyre inspections creates a more transparent and trustworthy service experience. By replacing visual estimates with precise digital data, TireBuddy helps businesses streamline workflows, empower technicians and ultimately support safer, more reliable vehicle assessments for customers.

Christoph Braunsberger, CEO, Anyline, said, “Our goal with TireBuddy is to equip technicians with the tools they need to make accurate, fast and confident decisions, an important message we’re bringing to the forefront at this year’s NADA Show. By providing objective, AI-powered data, TireBuddy delivers a far clearer path to cost savings, operational efficiency and customer transparency for retailers – benefits that matter at every level of their operation.”

Continental Innovates Tyre Technologies For Quieter Driving

- By TT News

- January 30, 2026

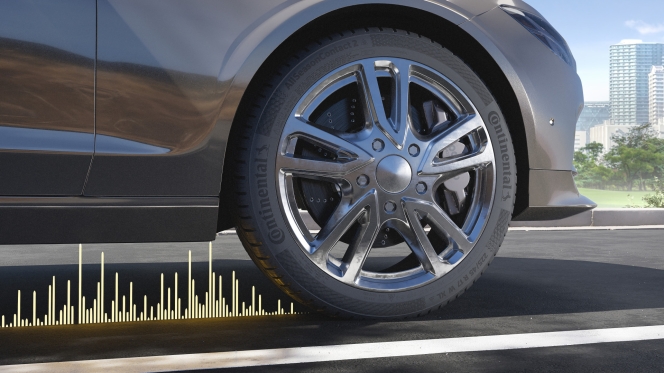

As urban areas around the world grow increasingly louder, traffic noise has emerged as a critical environmental and public health challenge. Recognised by health authorities as a major risk factor, this pervasive issue extends from European cities to megacities across Asia and Latin America. Continental is addressing this problem by pioneering tyre technologies that significantly reduce rolling noise, thereby contributing to quieter urban environments and enhanced in-vehicle comfort.

The transition to electric mobility has brought tyre noise into sharper focus. With the near-silent operation of electric motors replacing traditional engine sounds, the acoustic contribution from tyres becomes far more prominent, even at moderate city driving speeds. In response, Continental engineers have developed specialised solutions that target noise generation without compromising the safety, durability or performance of the tyre.

One such innovation is the Silent Pattern tread design, featured on models like the EcoContact 7. This technology disrupts the conventional, uniform arrangement of tread blocks that typically creates a rhythmic humming sound on pavement. By intelligently varying the spacing and angles of these blocks, the pattern breaks up this acoustic consistency. Furthermore, it is tuned to cancel out specific sound frequencies, akin to the principle behind noise-cancelling headphones. This results in a measurable reduction of traffic noise at speeds around 50 kmph, where rolling noise is most perceptible to pedestrians and residents.

For reducing noise inside the vehicle cabin, Continental employs its ContiSilent technology. This involves lining the inside of the tyre with a lightweight polyurethane foam that absorbs vibrations caused by the tyre’s contact with the road. By dampening these air vibrations, the technology can cut perceived in-cabin rolling noise by up to nine decibels – a reduction the human ear experiences as nearly halving the volume. This substantial increase in acoustic comfort is integrated into various product lines, including high-performance summer tyres, without affecting driving dynamics or efficiency.

The company’s commitment to low-noise mobility spans multiple vehicle segments. From the Conti Urban NXT for city buses to passenger car tyres like the EcoContact 6 Q and van tyres such as the VanContact A/S Eco, these products are designed to meet stringent noise standards. Consumers can readily identify these quieter options through regulatory labels, like the EU tyre label, which provides clear decibel ratings for external rolling noise. Through these continuous advancements in tread design and sound-dampening materials, Continental is systematically working to diminish the acoustic footprint of road traffic.

According to Achillefs Tsotras, head of Continental’s Tyre-Vehicle Interaction department, “Noise, especially traffic noise from cars, buses and delivery vehicles, is a major burden for people and the environment. With tyre technologies like ContiSilent and innovative tread designs, we are actively reducing rolling noise without compromising safety. This makes every ride noticeably quieter, benefiting drivers, pedestrians, residents and the environment alike.”

Comments (0)

ADD COMMENT